High Performance Galvoscanners

We offer complete integrated motion control and data acquisition systems with endless possibilities!

Have a question or want a personalized demo?

We’d love to hear about your galvoscanner requirements. Please send us a a message and we’ll be happy to answer or set up a meeting!

Polaris Motion is a motion control company that has been designing and manufacturing high-performance motion control and data acquisition systems for some of the world’s most advanced applications since 1994.

We respond quickly to questions, and our application engineers work closely with our customers to solve their problems.

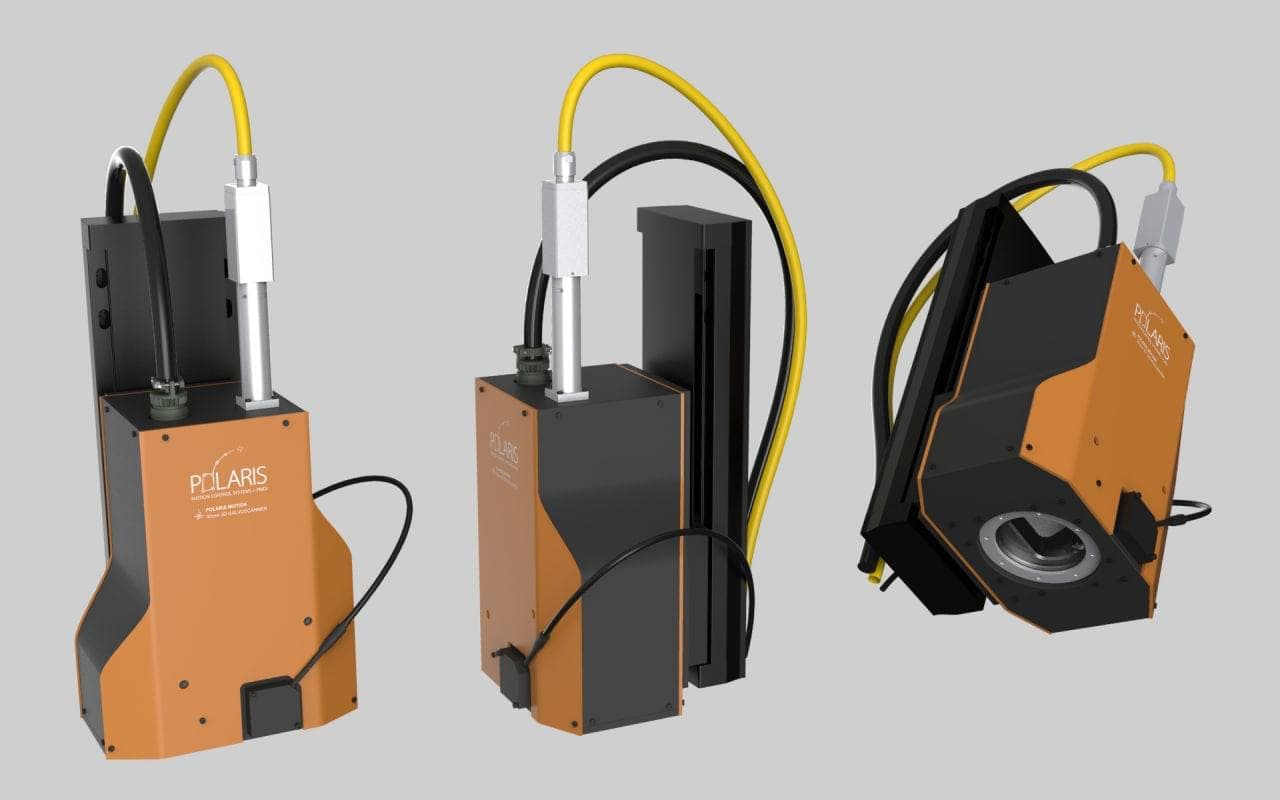

30mm Aperture with Advanced 3D Calibration

Polaris Motion’s 3D Galvoscanner has an aperture of 30mm, and may be ordered for a number of laser wavelengths including 1064, 512 and 355nm lasers. It provides superior speed and stability with its high-performance rotary and linear Galvanometer motors, and integrated mechanical design. Its linear focusing motor is a stiff, direct-drive design.

Advanced Field Flattening

Advanced field flattening and 3D calibration algorithms make certain the focus laser spot can move around accurately in the large work volume of the laser Galvoscanner.

Galvo Head Liquid Cooling for Optimal Operation

The internal temperature of the laser Galvo scanner runs cool, even at the highest working rates. This is due to externally located drive electronics. Even so, there are provisions for air and water cooling if high power beams are employed.

5-Axis Stage a 3D Galvoscanner Integration

Polaris Motion’s 3D Galvo scanner and a 5-Axis CNC stage may be controlled with a single Polaris UniverseOne™ motion control system. By using 5-Axis infinite field of view (IFOV) along with synchronized laser control, the highest quality multi-axis laser machine tool control is achieved.

Polaris 2D Galvoscanner

Polaris Motion’s 2D Galvoscanner has an aperture of 10mm. It may be ordered for a number of laser wavelengths, including 10.6 microns, and 1064/512/355nm. A customer may order a f-theta lens, a telecentric lens or they may use their own lens for a large number of scan field size and focal length options. Advanced, curve-based 2D lens correction algorithms guarantee the creation of accurate laser processed parts.

10mm Scanner Aperture with Gbps Real Time Motion Control

The Polaris 2D scan head natively integrates with the Gbps, real-time Mercury™ motion control network. The Polaris UniverseOne motion controller controls the scan head and stage axes for seamless integration and performance with 3-axis CNC machine tool stages.

By virtue of the Mercury real-time, Gbps high-speed motion network, stage servo error is communicated to the Polaris Galvo scanner in real-time for dynamic stage error compensation.

Testimonials

Have questions or want to see our technology in action?

We’re always happy to hear about your projects and help work on innovative solutions