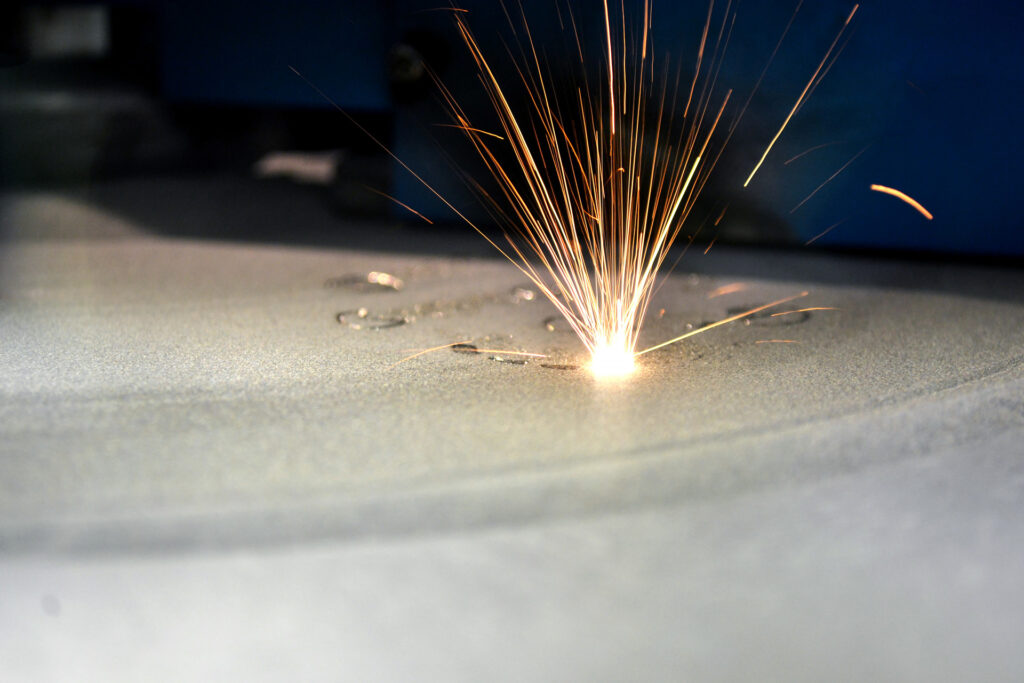

HIGH PERFORMANCE MOTION CONTROL

AND DATA ACQUISITION SOLUTIONS

We provide advanced software and electronics that convert your Machine Tool ideas into reality

MEET THE TEAM

HOW CAN WE HELP YOU?

We’d love to learn about your project and discuss how Polaris Motion can help.

Recent Articles

How can we help you?

We’d love to learn about your project and discuss how Polaris Motion can help.

Technical Support

Our number one priority is to support our customers using the latest tools. We answer all questions in a timely manner to enable our customers to deliver their machines into their markets as fast as possible.

Business Development

For people new to our website, we welcome you. Feel free to browse around and If you have any questions about our company or our products, we are happy to answer them.