6-Axis Robot Precision Processes

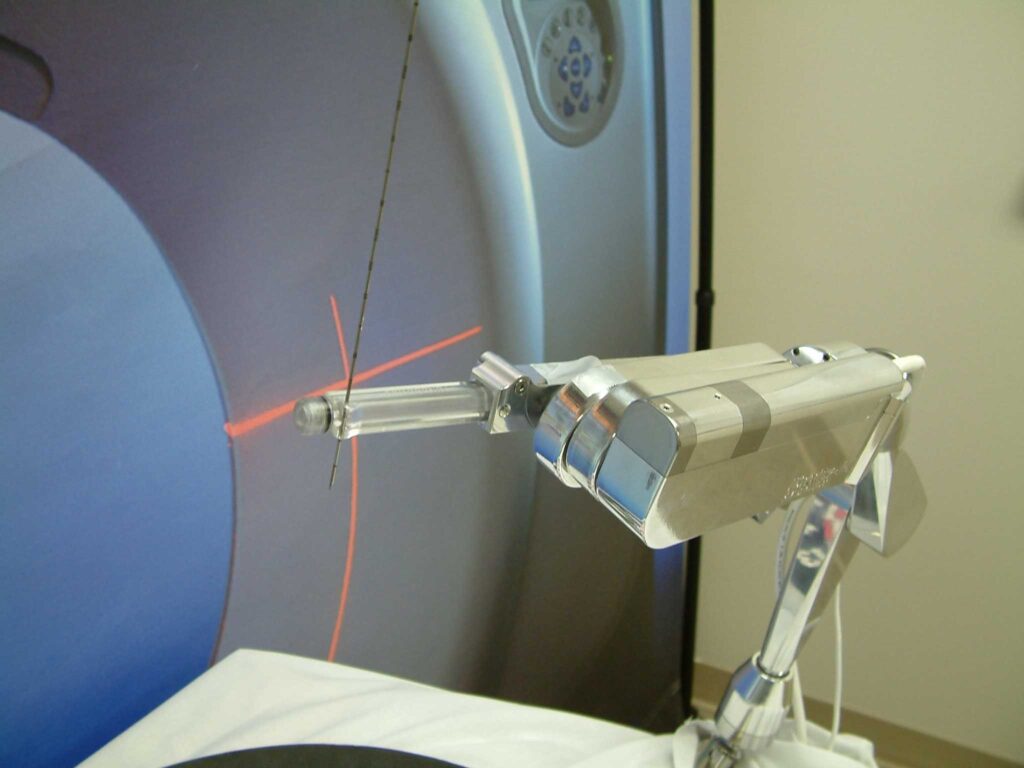

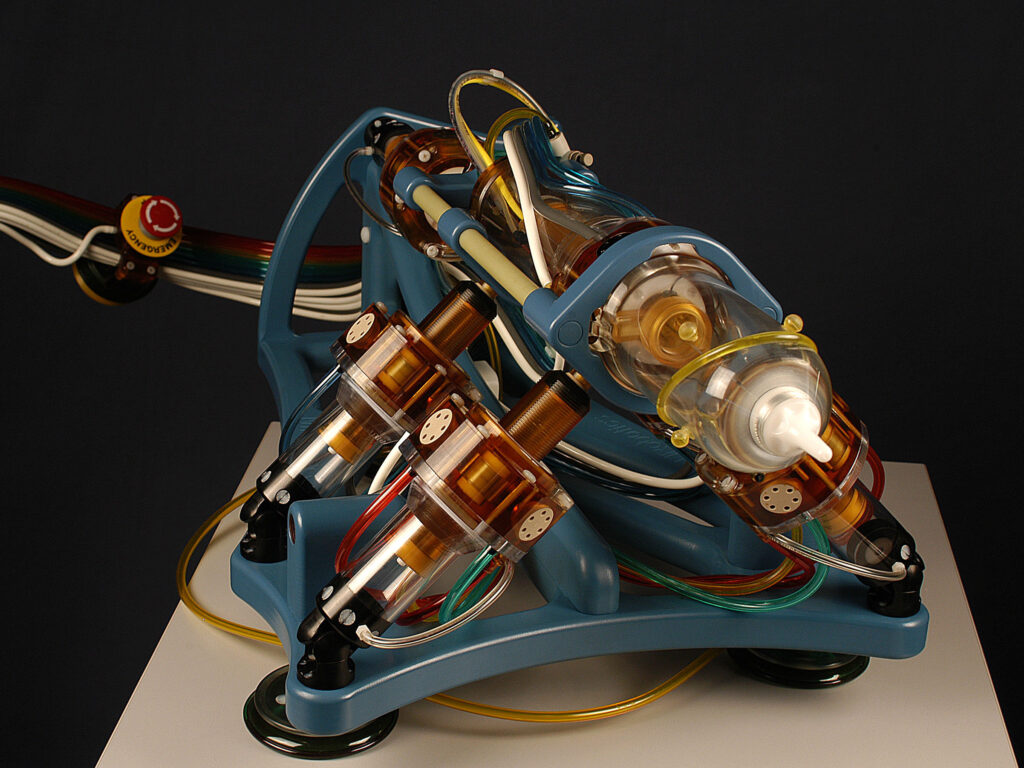

5-Axis and 6-Axis robot precision processes are accomplished using Polaris UniverseOne™ motion control systems. Applications range from laser cutting, laser welding, epoxy and tape dispensing, and tool center point control.

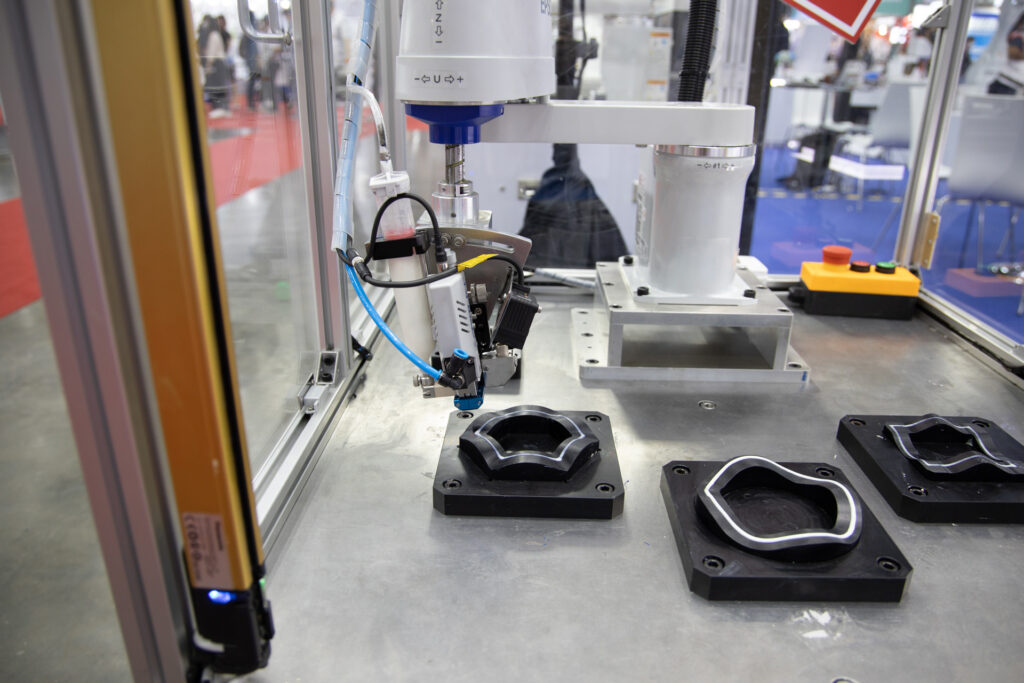

CAM software can be used to perform the path planning. The resulting G-code file is executed using the Polaris trajectory generator with lines, arcs and PVT cubic splines. Automatic path merging occurs between path segments. Inverse and forward kinematics map the robot Cartesian movements into robot joint motion. Many machine configurations are supported including standard 5-Axis CNC machine tool configurations and articulated robot arms.

For many applications, coordination between the tool and the Cartesian motion along the tool path is required. For the case of laser welding, the laser power delivery to the work piece is made proportional to the speed along the tool path and ramp up and ramp down are managed. For epoxy dispensing, the speed along the dispense path is made constant while the dispense fluid is applied at a constant volumetric rate.

Typical Features

Some Polaris features used in precision robot processes include:

- Robot inverse kinematics

- Tool center point control (TCPC)

- PVT cubic spline tool path generation

- Coordinated control of the tool path and the tool power or flow rate

- Cartesian G-code

Questions?

We’d love to help. Visit our question page to submit your inquiry.