Ultra Precision is our Specialty

Polaris UniverseOne motion control systems provide the components and technologies needed for some of the most precise and accurate ultra precision machine tools in the world. These machines operate at a resolution of 10nm or less and are used to fabricate precision components having the most demanding requirements.

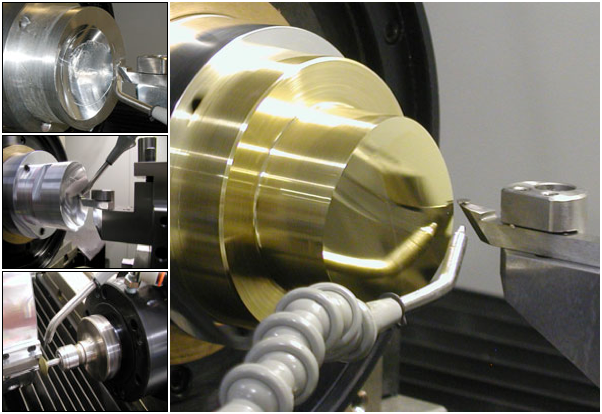

Single Point Diamond Turning

Single point diamond turning (SPDT) is an ultra-precision process used to create transmissive and reflective optical components from optical polymers, crystalline materials and non-ferrous metal alloys.

Compatible Machinery

The following ultra precision machine tool types use Polaris UniverseOne™ motion control systems:

Single Point Diamond Turning (SPDT) Lathes

Ultra Precision Grinding Lathes

Ultra Precision Freeform Mills & Lathes

Precision Diamond Fly Cutting Machines

Ultra Precision Drum Roll Lathes

Typical Features

Key Polaris Motion technologies used to make ultra precision motion control and machining possible include:

- Picometer resolution position measuring technology

- Servo feedback control with feed-forward and digital filters

- Low noise PWM and linear drive technology

- 5-Axis and 9-Axis G-code machining

- Limited jerk trajectory generation

- Line, arc and spline trajectory generation

- Tool path merging

- G-code look ahead

- Cutter compensation

- Large, comprehensive set of G-code commands

- Paramacro G-code extension

- Tool center point control (TCPC)

- Ability to create custom G-codes and M-codes

- Manual data input mode

- Handwheel and joystick control

Questions?

We’d love to help. Visit our question page to submit your inquiry.