Controlling the Delivery of Laser Energy

Laser control is required for many manufacturing processes such as cutting, drilling, welding, etching, engraving and ablation. Precision laser control is needed for powder bed fusion (PBF) and for directed metal deposition (DMD). Lasers are used for material altering processes such as annealing and quenching for metals, and modifying impedance in semiconductors.

Continuous Laser and Pulsed Laser Support

For each of these processes, there is a preferred technique for controlling the delivery of laser energy. The two broad classes of lasers are continuous wave (CW) and pulsed. CW lasers may be lower cost and have the advantage of high average power. Pulsed lasers have a lower average power, but the short pulse photon energy breaks the material’s chemical bonds instead of burning. The heat affected zone (HAZ) is minimized, cuts are clean and material post processing is often unnecessary. In Polaris Motion’s laser control suite, both CW and pulsed lasers are fully supported, along with nanosecond to femtosecond, CO2, infrared, and ultraviolet lasers. Coordination of stage and Galvo scanner motion is an integrated capability with advanced features such as stitching and infinite field of view (IFOV).

Some available techniques include:

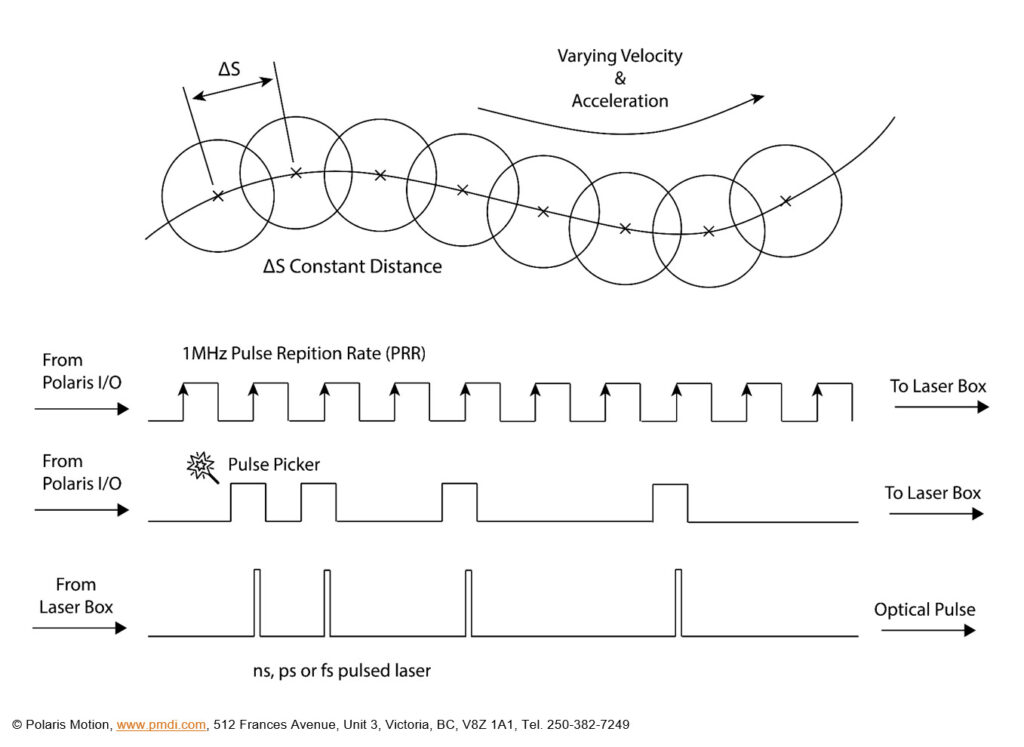

- Fixed pitch laser triggering for pulsed lasers

- Pulse on demand (POD) for pulsed lasers

- PWM duty cycle control for CW lasers

- Analog laser pulse shaping (ALPS) for CW lasers

Multi-Dimensional Precision

Using the time protocol of Polaris Motion’s patented, Gbps real-time network, Mercury™, and other advanced FPGA algorithms, continuous laser and pulsed laser control is exactly synchronized with multi-dimensional motion. Laser control is precisely delivered whether the trajectory is a line, arc, spline or a merged combination move.