In Process Quality Assurance for 3D Metal Printing

The adoption of 3D metal printing is accelerating rapidly. This includes the processes of powder bed fusion, selective laser sintering, selective laser melting, and direct metal deposition. All of these processes are additive as they add material to create the finished part, as opposed to removing material away from stock. In general, the field is called additive manufacturing (AM).

Limits of Quality Control

The field is promising, however questions with respect to quality linger and large-scale adoption of metal AM processes has not yet happened. Current methods of quality control include destructive testing and CT scanning. Both of these techniques are time consuming and costly, and they don’t provide a path toward in-process monitoring or the chance for in-process repair.

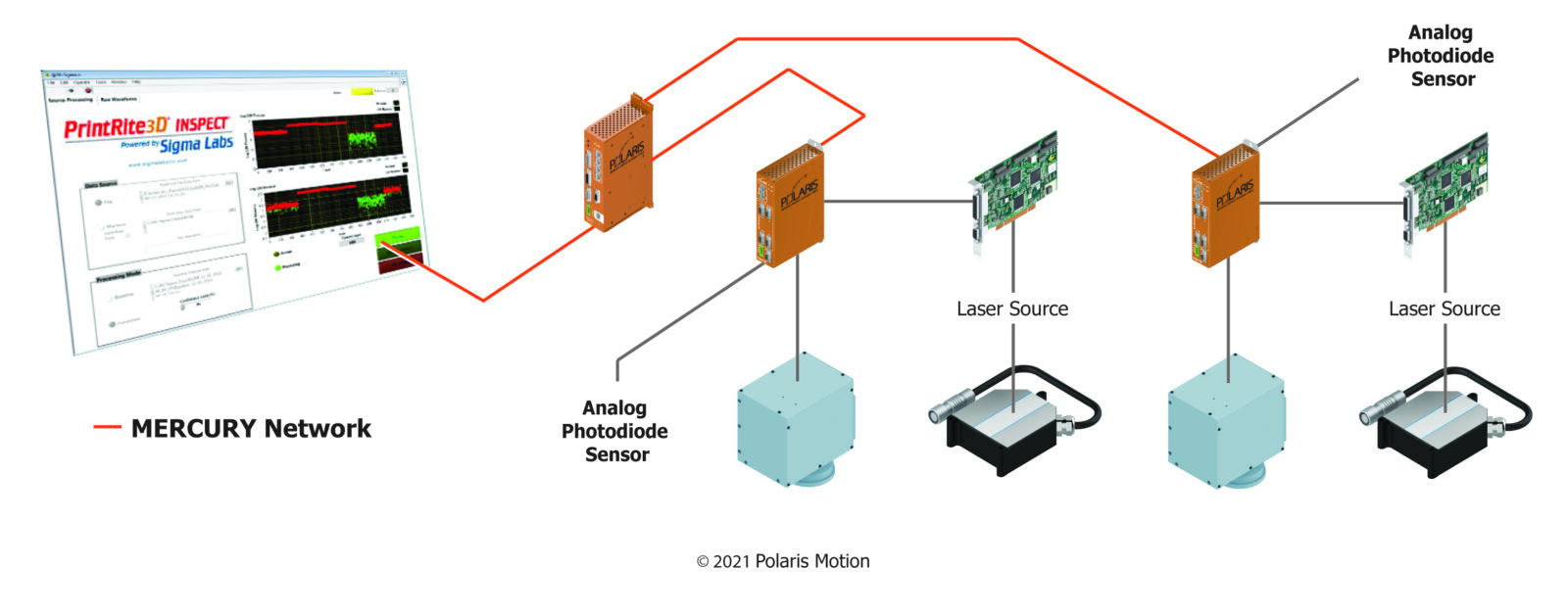

However, new techniques are emerging to help overcome these obstacles to quality. A Polaris UniverseOne™ synchronous data acquisition system is being used as an integral component in an advanced In Process Quality Assurance (IPQA®) solution from Sigma Labs.

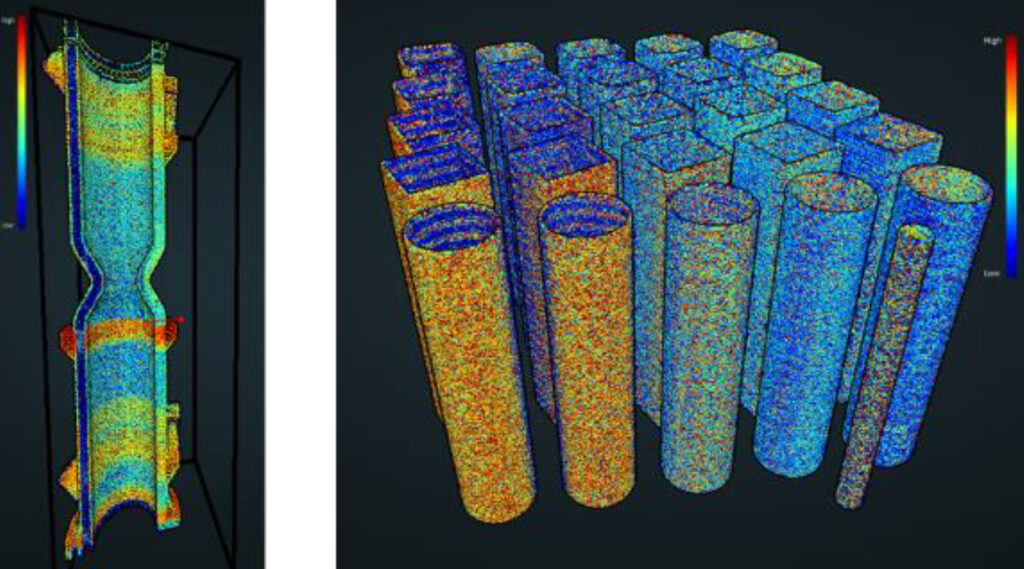

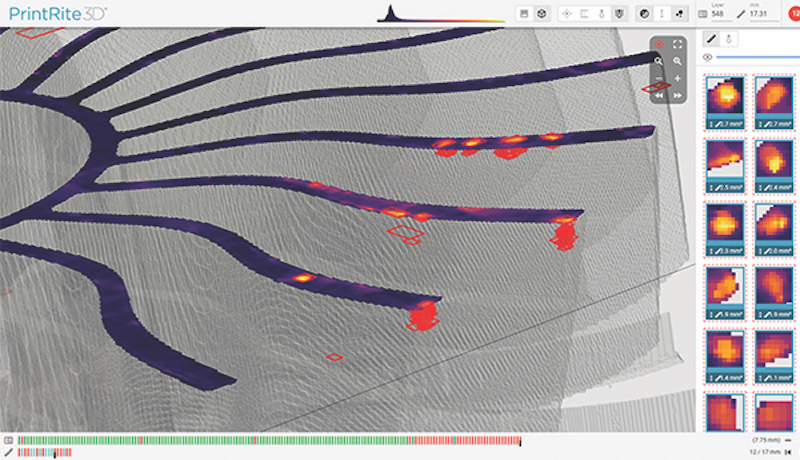

The Polaris Motion real-time, high throughput, Gbps data acquisition system integrates with 3rd party Galvo scanner electronics. This makes the synchronized, high-speed collection of real-time Galvo scanner position data and sensed melt-pool data possible. Our customer’s advanced software stitches together a real-time quality map one layer at a time. Real-time process adjustments are made to create high quality certified parts.

The simultaneous real-time collection of melt pool data from multiple Galvo scanners is supported.

Typical Features

Some Polaris features that are useful for 3D metal printing IPQA® include:

- Real time, multi-channel Gbps data acquisition

- Real time integration with SL2-100 Galvo scanner systems

- Integration with multiple simultaneous Galvo scanners.

- Ability to support data acquisition for multiple Galvo scanners

- High-resolution, high-speed analog to digital conversion

- High speed streaming of acquired data

- Real time, data acquisition network time protocol

- Easy-to-use data acquisition software API

IPQA is a registered trademark of Sigma Labs

Questions?

We’d love to help. Visit our question page to submit your inquiry.