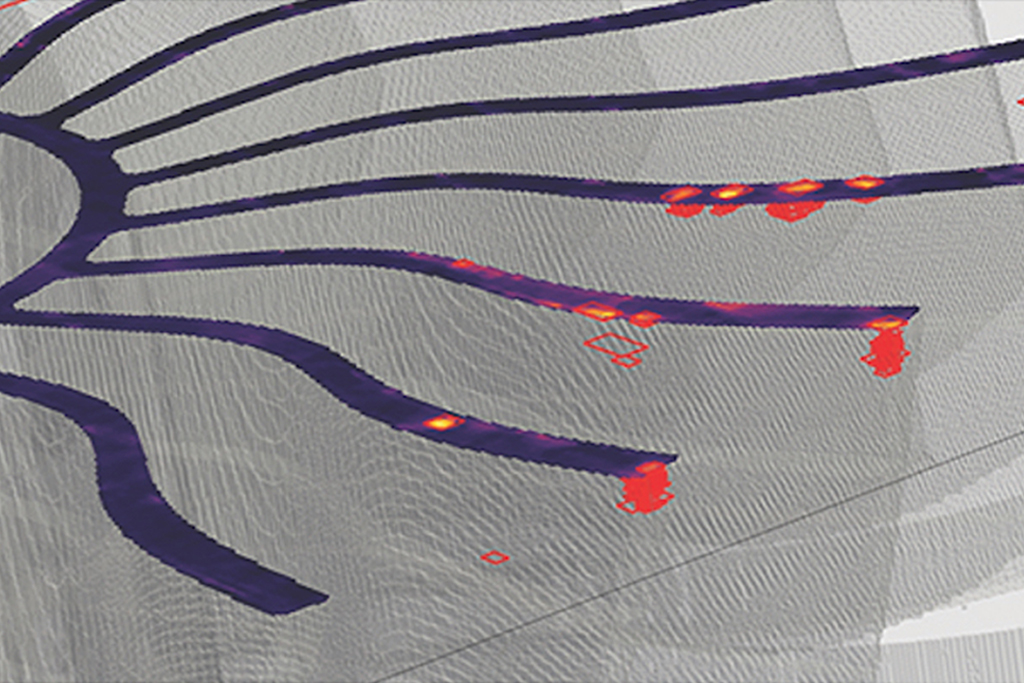

In Process Quality Assurance (IPQA™)

The obstacle to production scale 3D metal printing of automotive and aerospace components is quality and reliability. To overcome this reliability hurdle, customers are using Polaris ultra-high throughput data gathering electronics for in process (IPQA®) quality assurance systems.

>>Learn More

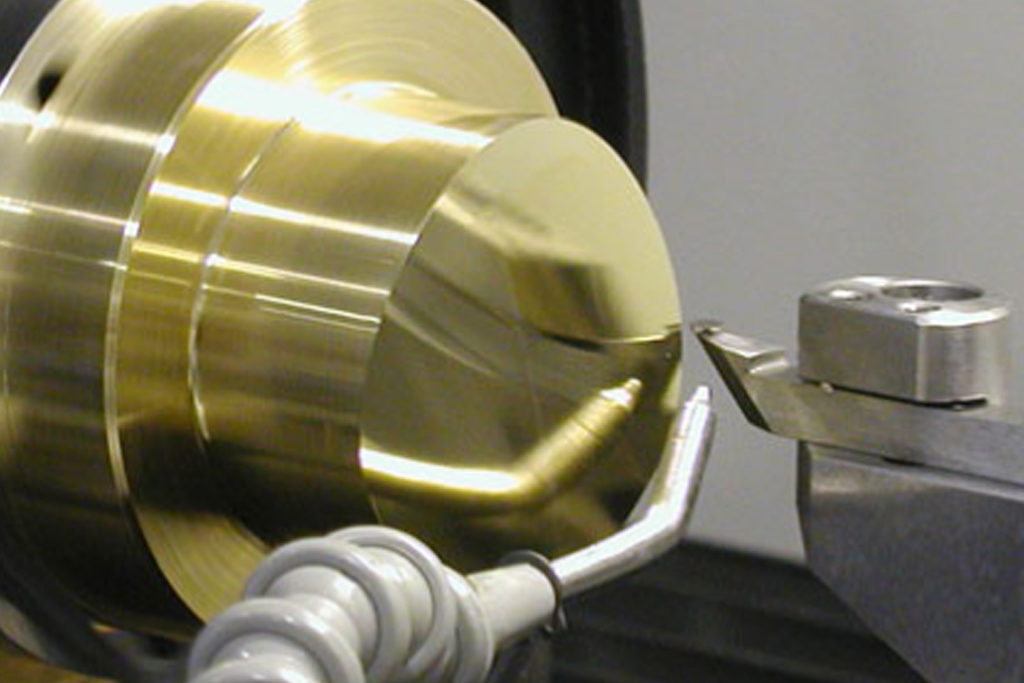

Ultra-Precision Machining

Polaris UniverseOne motion control systems are being used to deliver nanometer form and surface finish for ultra-precision CNC machine tools. Machine configurations include single-point diamond turning lathes, drum roll lathes, fly cutters and optical grinding machines.

>>Learn More

Ultra Precision CNC Spindle Control

Ultra precision CNC machine tool spindles are controlled using a Polaris UniverseOne motion control package. Speeds up to 100krpm are achieved with low jitter. Advanced encoder and torque compensation techniques are used.

>>Learn More

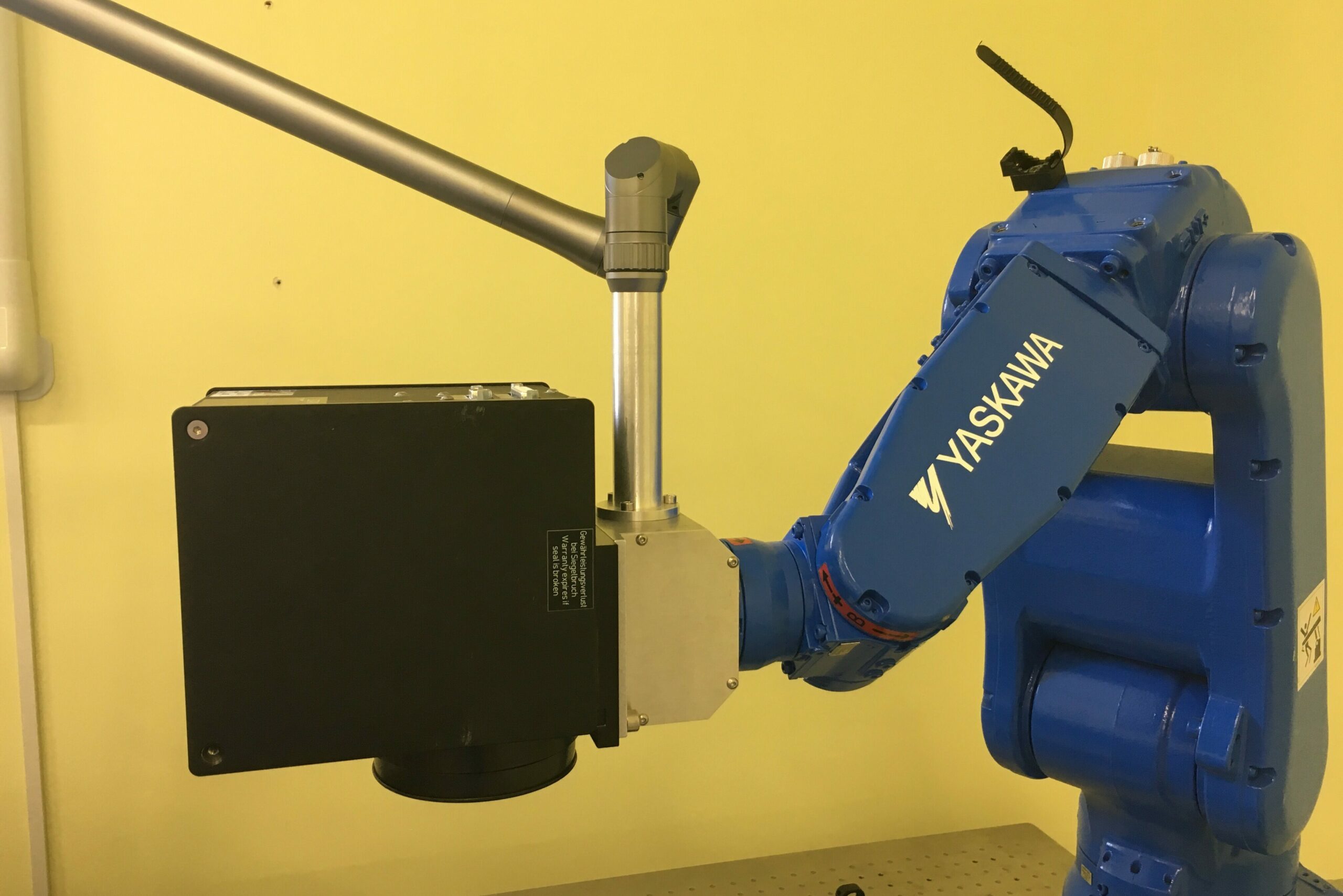

Robot Precision Processes

Polaris UniverseOne motion control systems are used for robot precision processes such as precision epoxy and tape application on curved metal and glass surfaces. Forward and inverse kinematics are employed. Cartesian G-code is used for easy programming.

>>Learn More

Aerospace Test Systems

Polaris UniverseOne control systems deliver an immediate response to commands originating from a flight motion computer. Aerospace navigation sensors are tested according to demanding test flight paths. Polaris systems control rate tables and Gimbals precisely.

>>Learn More

Vehicle Test Systems

Polaris motion control and data acquisition systems are being used for advanced vehicle test systems. The Polaris system provides the tools necessary for synchronization of throttle control with measurement of speed, torque, oxygen and carbon dioxide.

>>Learn More

Questions?

We’d love to help. Visit our question page to submit your inquiry.