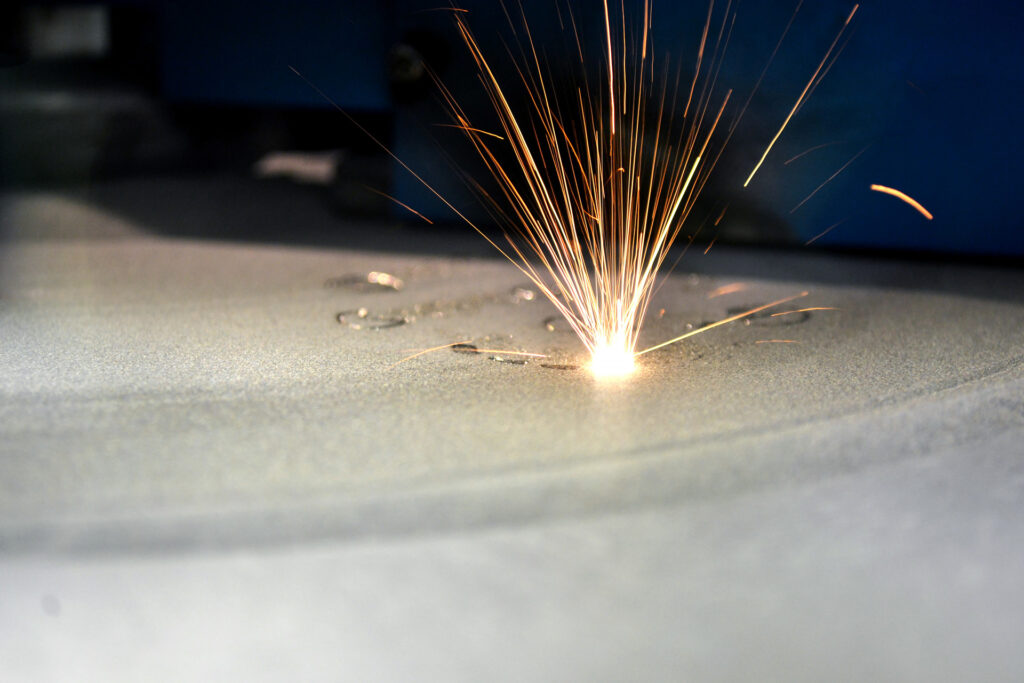

Laser Additive Manufacturing (AM)

Polaris UniverseOne™ motion control systems are ideal for metal additive manufacturing. One controller is used for multiple 3D Galvo scanners. Powerful scanner field calibration enables large accurate parts, and high throughput data acquisition enables advanced IPQA® technology.

>>Learn More

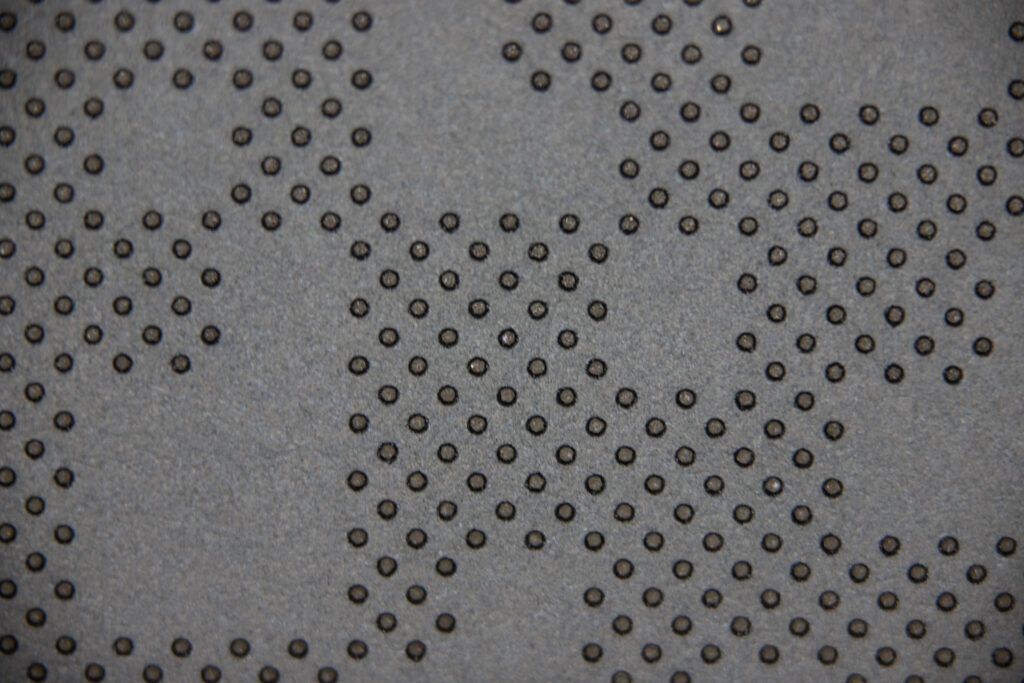

Laser Micromachining

The mobile and medical device manufacturing industries rely on fast, precision laser technologies for micro machining processes. Polaris UniverseOne motion control systems are used for laser ablation of ITO surfaces and high speed, high volume via hole drilling.

>>Learn More

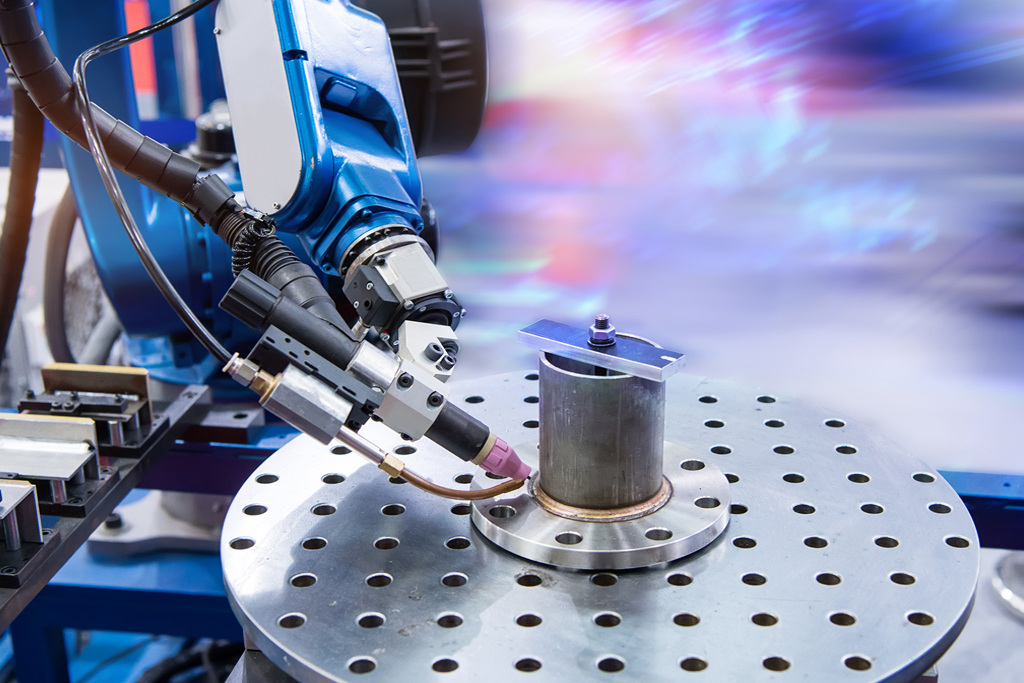

Laser Precision Welding

Polaris UniverseOne™ motion control systems are being used for precision metal welding applications. From tube welding to multi-axis robot seam welding, a Polaris Motion control system offers the capabilities and tools needed to complete the job.

>>Learn More

Laser Surface Structuring

Polaris UniverseOne™ motion control systems are ideal for 5-Axis laser surface structuring applications. Precision features are created on complex curved surfaces using femtosecond lasers. Hydrophobic and hydrophilic properties are achieved for increased operational efficiencies.

>>Learn More