Speed at Microscopic Levels

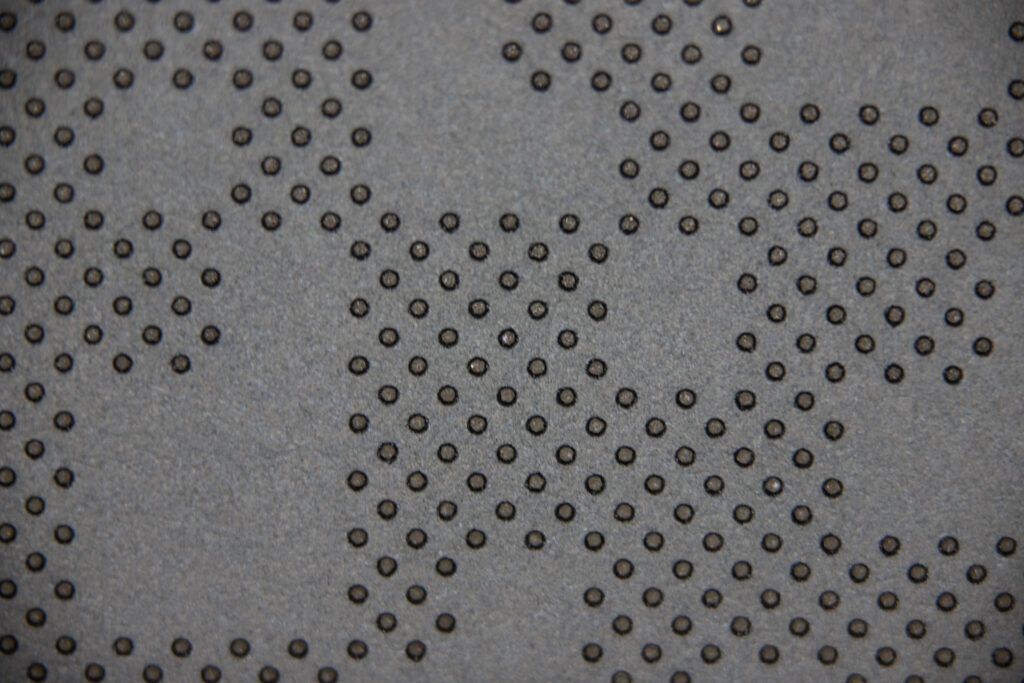

Polaris UniverseOne™ motion control systems are being used for precision laser drilling applications. Drilling thousands of micrometer scale holes is a common need in many applications, from bio-medical filters and micro-fluidics, to semiconductor wafers, fuel cells, flex circuits, photographic pin holes a more.

Wide Range of Material Compatibility

Materials can be transparent polymers, glass, crystals and metal alloys. Circular and linear interpolation, along with high speed, precise laser triggering is used to create thousands of holes in seconds.

Flexible Cutting Variations

Holes can be made using single shot and percussion methods. Trepanning and helical motion can be used. Micromachining arbitrarily shaped holes can be achieved. For parts that are larger than the Galvo scan head’s field of view, infinite field of view (IFOV) may be employed to eliminate stitching errors and to achieve the highest quality.

Typical Features

Features useful for precision laser drilling:

- Optimized feedback filters

- Arc primitives optimized for speed

- 3D Galvoscanner for helical drilling

- IFOV for parts larger than the Galvo scan field