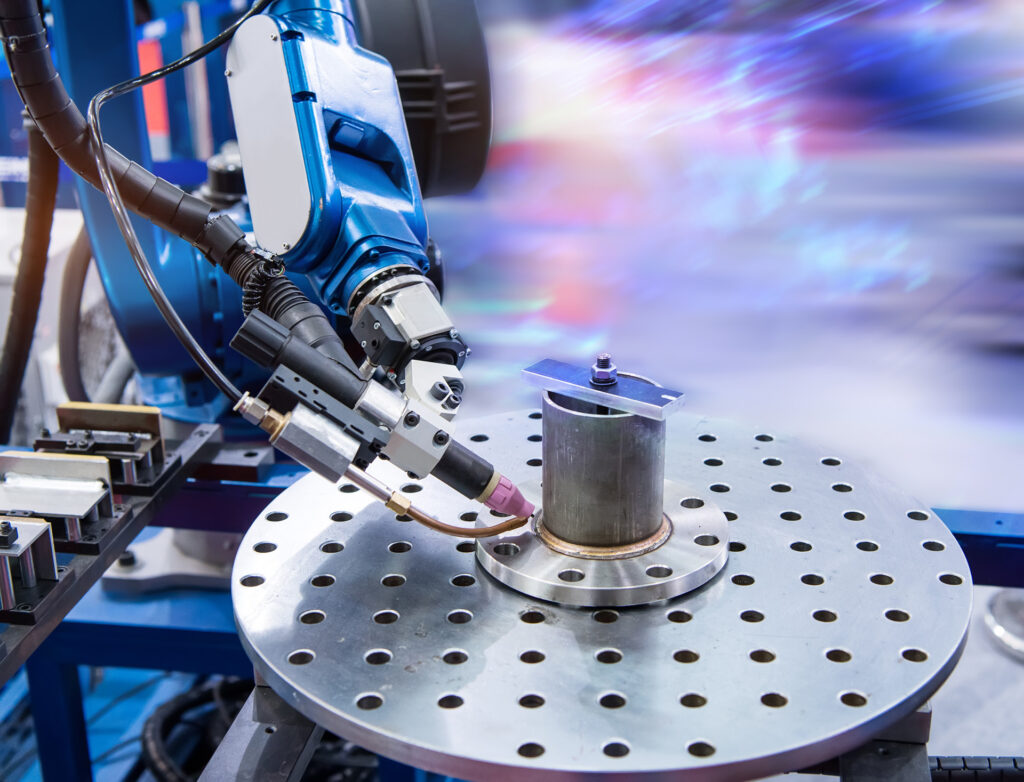

Precision Laser Welding Capability

Polaris UniverseOne™ motion control systems are being used for precision laser welding applications, including both spot and seam welding. Some advantages of laser welding compared to traditional techniques include the ability to weld a wide variety of materials, including both polymers and metals, and the ability to precisely, and simultaneously control tool path motion and laser power deposition. By delivering energy precisely, weld quality repeatability in a single part and over many parts can be exactly controlled. This leads to a near perfect weld and a tiny heat affected zone over an entire production run.

Effortless 3D Control

Polaris motion’s robotics capabilities are useful when it comes to welding complex 3D parts. With Polaris Motion’s ability for high speed, simultaneous data collection, it’s possible to analyze the melt pool in real time for in process quality assurance (IPQA®).

Typical Features

Features useful for laser hole drilling:

- Variable laser power control

- Constant velocity control along a seam

- Wobble using line, circle, figure eight and infinity

- Lead in and lead out path segments

- Tool center point control (TCPC)

- Robot remote welding