Polaris Motion has the right motion controllers for your advanced application.

From modular, high-performance hardware to powerful software that can simulate your processes, we have the tools for your tools.

Motion Control Network

Mercury™ is Polaris Motion’s patented, Gbps, ns-precision, real-time network optimized for motion control. Mercury connects Polaris motion controllers with all of the drives on the network. Common systems use between 2 and 32 drives, but more than 100 drives can be on the network.

>>Learn More

Servo Motor Drives

Polaris drives deliver controlled power to a large variety of high performance motors. Powers range from sub hundred Watts to multiple kWatts. Single-phase and three-phase, linear and PWM drives are provided. The drives can be used for BLDC motors, spindle motors, voice coils and Galvo scanner motors.

>>Learn More

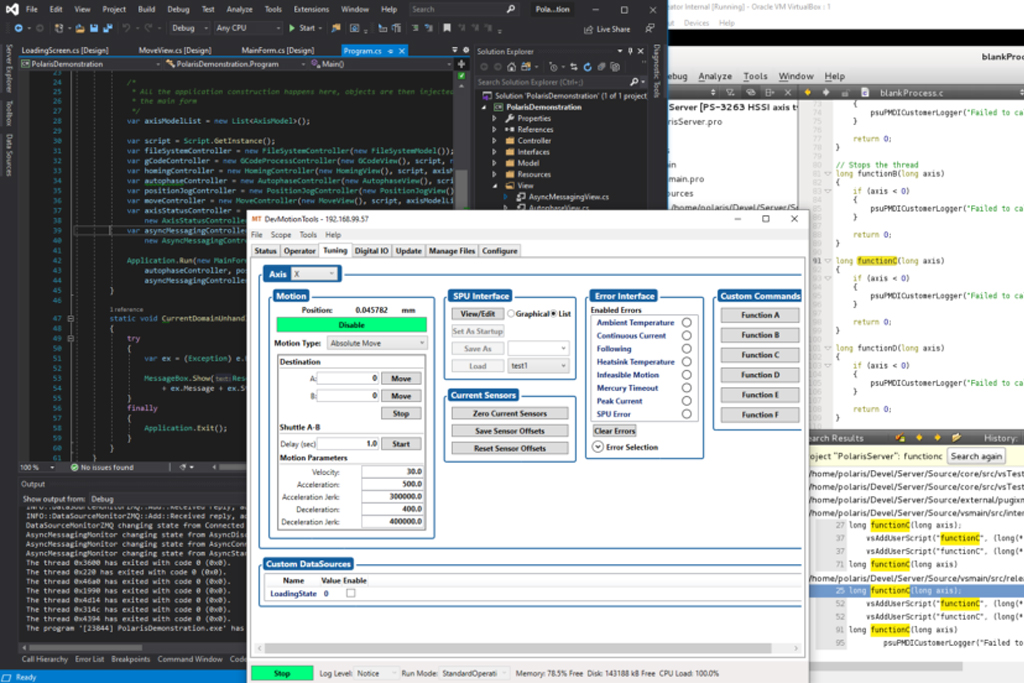

Application Development Software

Polaris OEM customers use Polaris software application development tools to create their own custom HMI applications. Tools are available to develop custom embedded code inside Polaris’ Intel/Linux based motion controller. Client HMI applications are developed using Polaris Motion’s extensive software libraries.

>>Learn More

Polaris G-Code Engine

Polaris Motion has been developing its G-code technology since 1996. It is a high-performance, reliable product. All of the fundamentals are supported, as well as new extensions such as “Cartesian G-code.” Up to nine axes of G-code are included (XYZ-ABC-UVW) and OEM customers can implement their own G-code extensions.

>>Learn More

Precision Laser Manufacturing

Polaris specializes in laser and motion control for demanding laser-based manufacturing processes, including laser micro machining, additive manufacturing and laser surface structuring. Key technologies include tight synchronization of laser control with multi-axis tool path generation.

>>Learn More

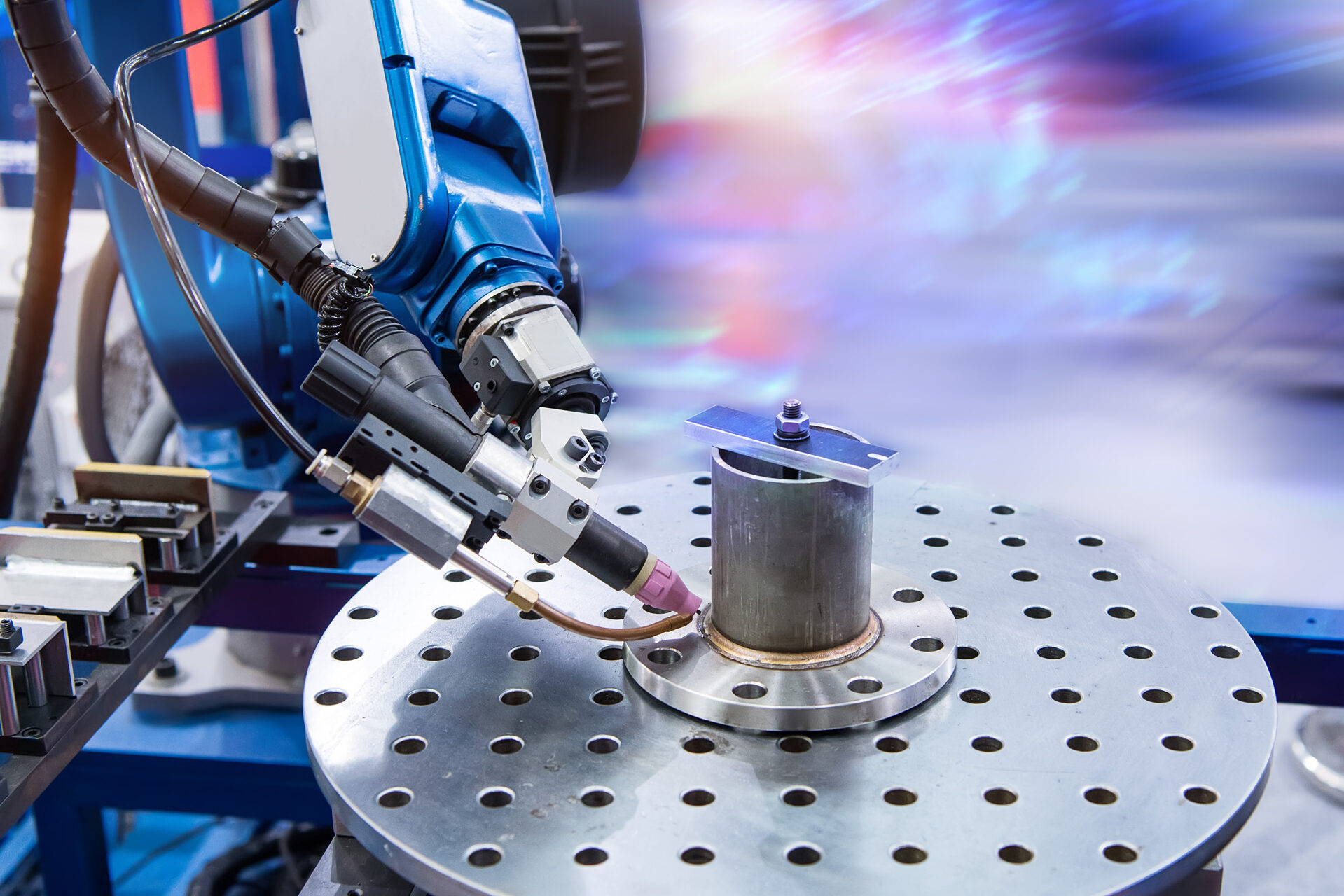

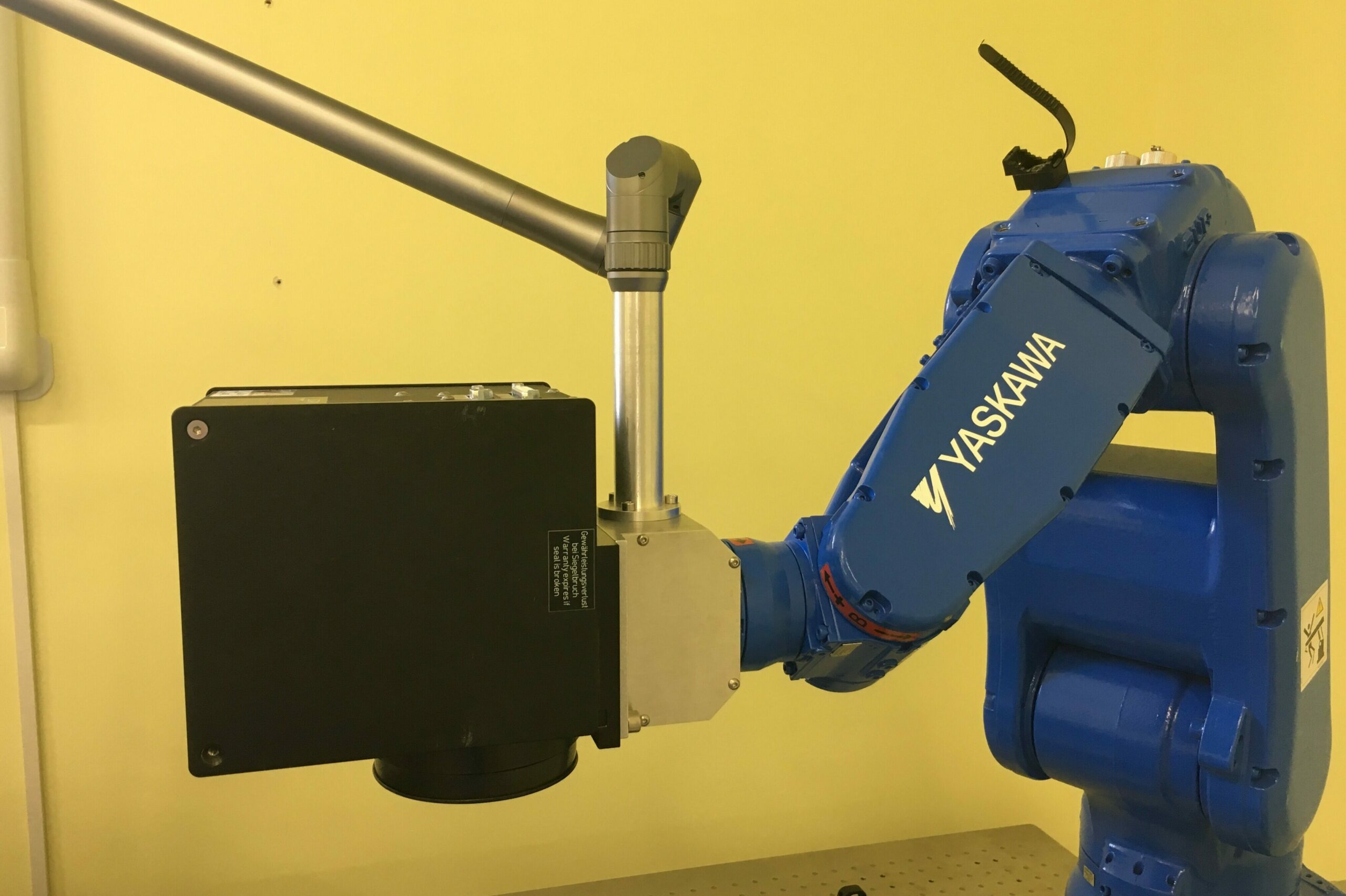

Robots & Multiaxis Machines

Polaris Motion uses advanced forward and inverse kinematics to make the control of multi-axis CNC machine tools, serial and parallel robots possible. The toolpath is described in the Cartesian coordinate system, and the actuator movements are computed automatically.

>>Learn More

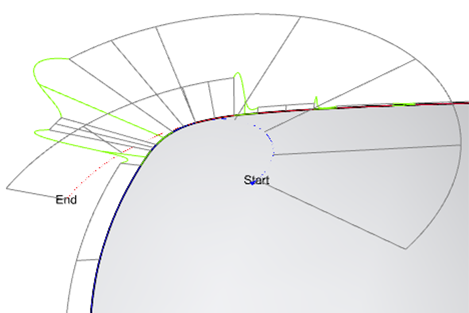

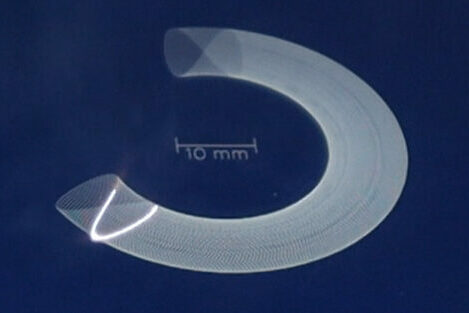

Infinite Field of View (IFOV)

A laser Galvo scanner is fast but it’s field of view can be limited. A stage has a large area but it is slow compared to a Galvo scanner. Using the IFOV algorithm, stage and Galvo scanner motions are coordinated in a sophisticated manner enabling the creation of a large detailed parts in record time. Stitching errors are eliminated.

>>Learn More

Laser Control Technology

Polaris laser control technology is used to control continuous wave(CW) lasers, as well as nanosecond, picosecond and femtosecond pulsed lasers. A wide variety of techniques are employed including fixed pitch triggering and pulse-on-demand (POD) for pulse lasers and analog laser pulse shaping (ALPS) for CW lasers.

>>Learn More

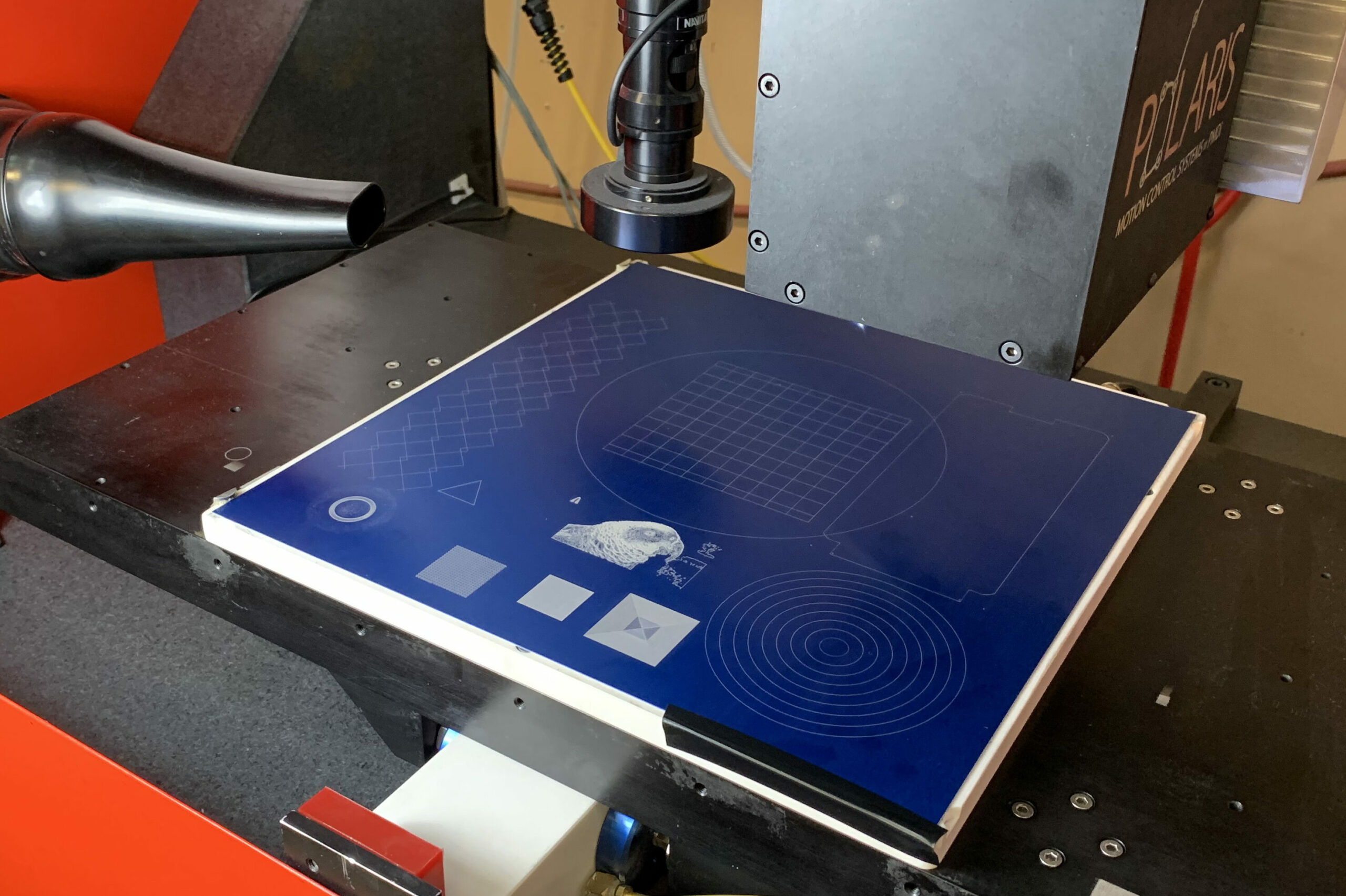

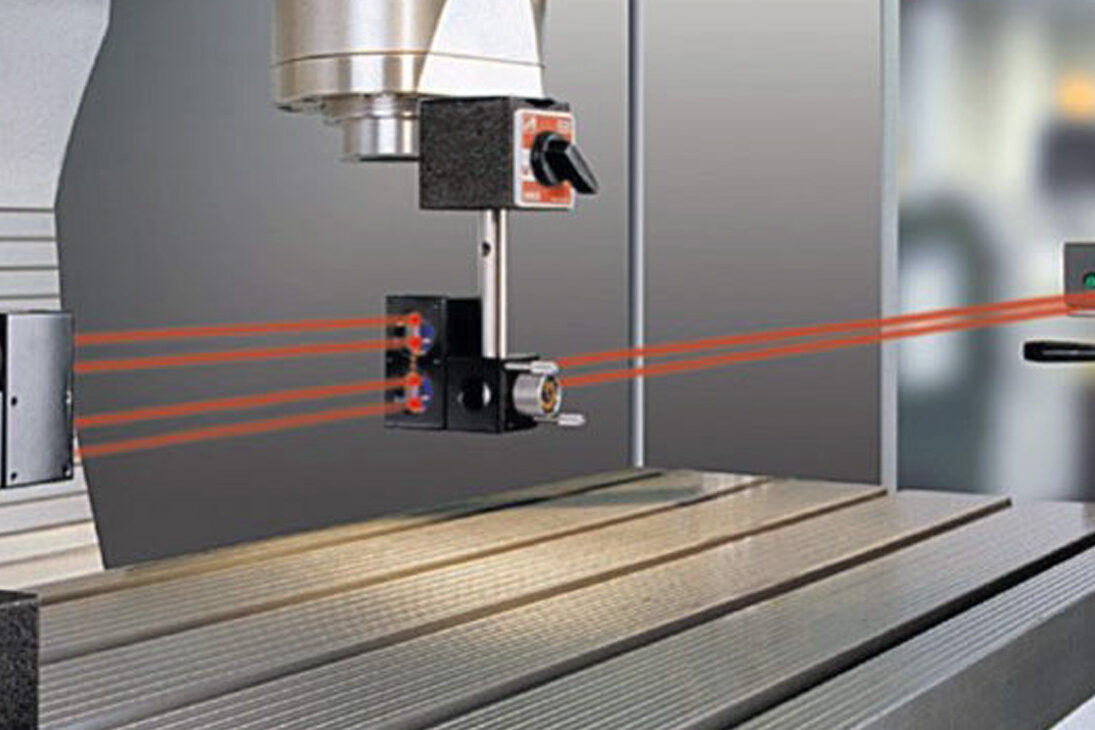

Mechanical & Optical Calibration

Polaris UniverseOne motion control systems have powerful software functions for machine tool calibration. There are a number of levels of calibration, including single axis encoder and backlash calibration, XYZ stage calibration, and 2D and 3D optical calibration for Galvo scanners.

>>Learn More