Maximally-Constant-Speed Toolpath Generation

In today’s competitive manufacturing landscape, producing components on a large scale—from thousands to millions of parts—is fundamental to industrial operations. Efficient manufacturing is crucial for economic viability and optimized throughput.

To achieve this, many facilities increasingly rely on advanced automated machinery that dynamically adjusts speeds along the tool path. This capability lets machines accelerate on straight sections and decelerate at corners, optimizing production time.

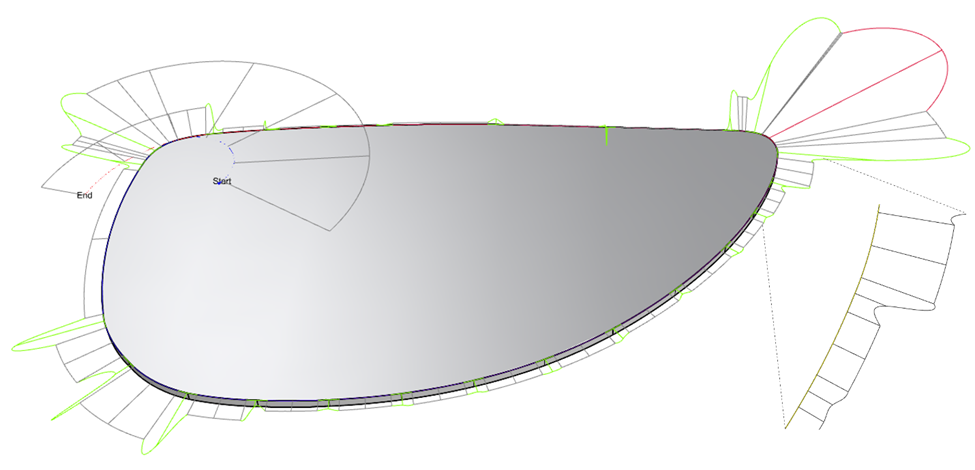

(Fig. 1) Constant speed scoring of an eyeglass part: PolarisCAM 2D showing curvature graph with transition between drawing primitives.

Variable speed motion is suitable for applications where precision is less critical, such as rough cutting with CNC machines where the exact surface finish is not a priority, or pick-and-place operations that require speed over precision.

However, many manufacturing processes rely heavily on constant speed tool path execution to meet specific quality metrics. Some of these include (1) consistent epoxy dispensing (2) better fusion in seam welding, (3) uniformity of laser energy deposition for glass scoring.

Other constant-speed manufacturing processes that significantly benefit both form and surface finish include high-precision metal milling, turning, grinding, waterjet cutting, and single-point diamond turning.

Our firm’s highly talented scientists and developers have responded by creating new techniques and algorithms to optimize throughput in constant-speed operations, providing cutting-edge performance. These advancements allow easy integration.

By adopting this technological innovation, manufacturers can significantly enhance their production capabilities, efficiently meeting current demands and preparing for future manufacturing challenges.

The integrated workflow provided by the new, optimized constant-speed process is easy to use:

- Input the CAD drawing

- Input the contour displacement tolerance

- Configure the kinematic ability of the CNC machine tool

- Output the constant-velocity-ready G-code file using CAM

- Execute the G-code file on the CNC motion controller

This new constant speed process provides important advantages, for example:

- Guaranteed part completion

- Best constant feed rate

- Best constant feed rate variation

- Easy creation of G-code part files

- Better surface finish on parts

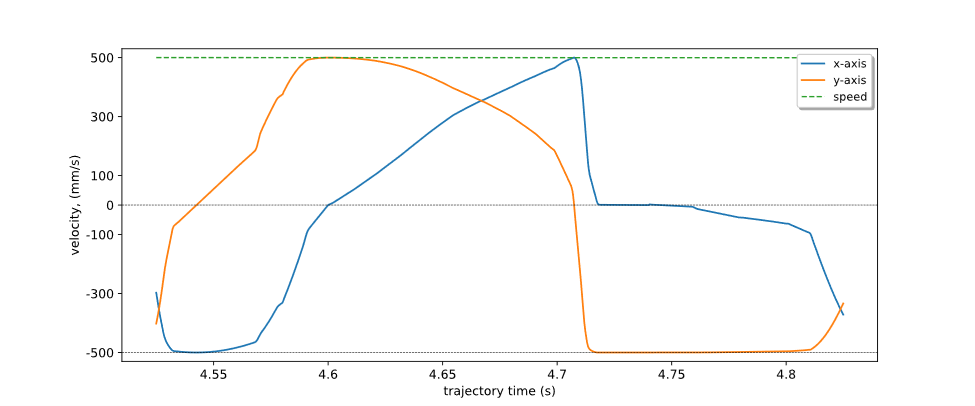

(Fig. 2) Constant speed scoring of an eyeglass part: The x-axis, y-axis, and the net constant commanded velocity generated from PolarisCAM 2D.

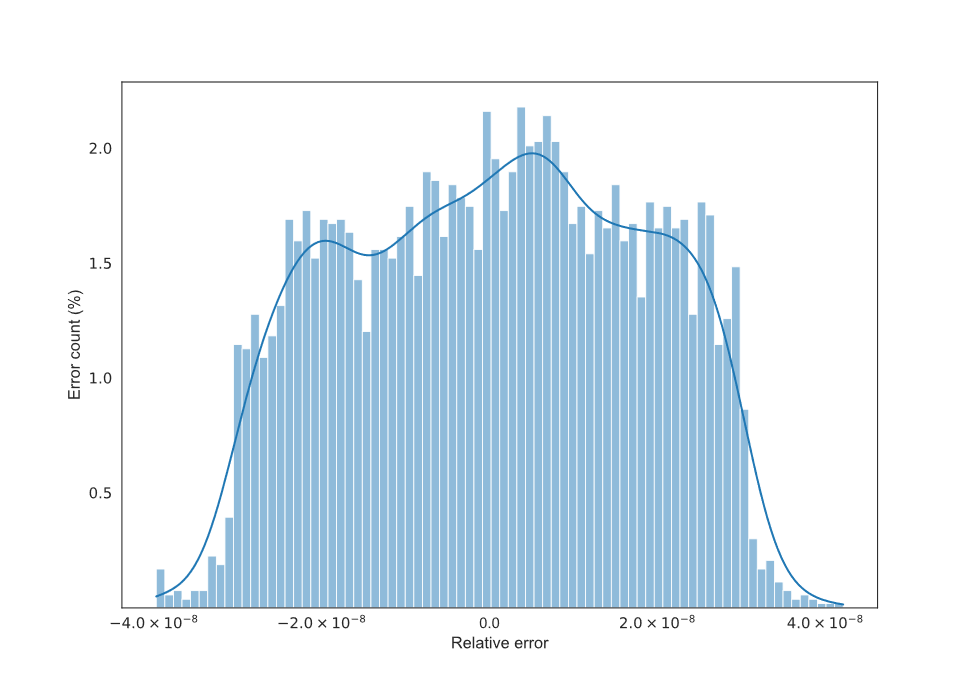

(Fig. 3) Constant speed scoring of an eyeglass part: Histogram illustrating the deviation between the desired 500 mm/s constant speed and the generated setpoint speed.

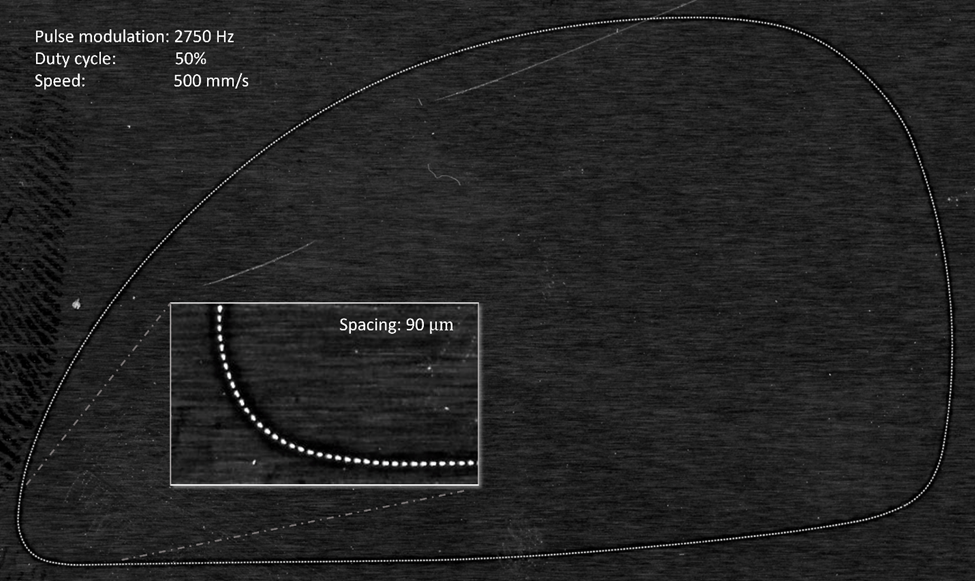

(Fig. 4) Constant speed scoring emulated by an eyeglass part: 500 mm/s constant speed trajectory marked using a laser with a 2750 Hz pulse repetition rate. Duty cycle 50% at 20 kHz setpoints.

Mile Erlic, Ph.D.

Polaris Motion

512 Frances Avenue

Victoria, BC, V8Z 1A1

Canada