Achieve the Next Level of Performance for your XYZ Stage, Galvoscanner and Laser

Achieve Sub-Micron Print Accuracy and Maximize your Throughput

Using a Polaris motion control system, XYZ stages Galvoscanners and precision lasers can be coordinated and synchronized for sub-micron print accuracies and maximum throughput. Motion is natural, minimal time is needed for setup and there are no stitching errors.

Take advantage of the long strokes offered by a stage and the high speed of a Galvoscanner to create large parts with fine detail with accuracy and speed. With our advanced algorithms, the scanner behaves as though it has an unlimited field of view, a technique called “infinite field of view (IFOV)” in the industry.

A DXF or STL part file is taken as an input and the control system automatically decides what the Galvoscanner does and what the stage does. Large motions are taken care by the stage and moves around corners are done rapidly by the Galvos. There is no need to do step and scan.

Polaris offers a general solution for IFOV. As such minimum time is needed to set up part files, and the jobs are well behaved, smooth and accurate.

Our Polaris motion control system is ideal for 3D printing, marking, engraving, cutting, ablation and other laser processes.

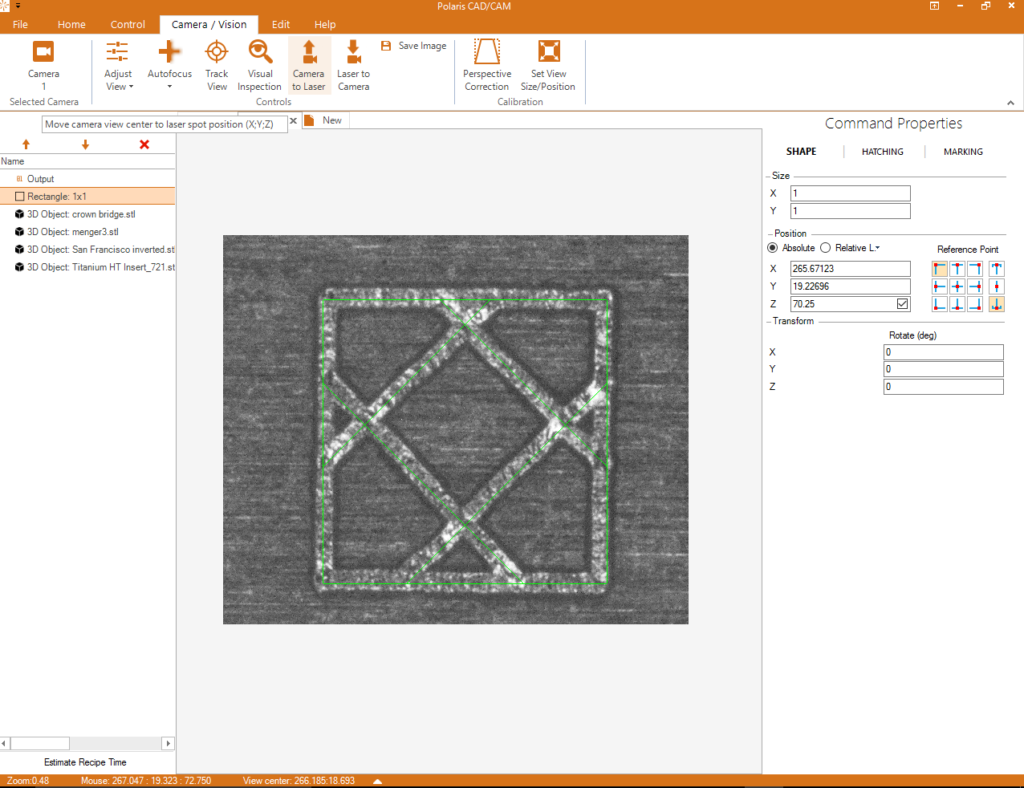

Polaris CAD/CAM: Increase Your Productivity, Create Parts, Hatch and Operate your Machine Directly

With Polaris CAD/CAM (PCC), you’re able to import and execute all common part files, including DXF, STL, Gerber and NC Drill files.

You may draw objects directly, including lines, circles, arcs and rectangles. You can draw them by hand and/or add precise parameters for size and position. You can draw polylines and polygon shapes. All closed shapes can be hatched. Select motion speed and laser parameters for each shape, groups of shapes or the whole recipe.

Recipes can be created. All the parameters in the recipe such as size, position, motion and laser parameters can be entered as variables. Logical commands may be used to create complex, flexible and easy-to-control laser machining recipes. Use mathematical expressions, constants and formulas to create complex geometries.

Polaris CAD/CAM may be used to control stages and Galvoscanners separately or in a coordinated fashion. Infinite Field of View (IFOV) may be used to combine slow large stroke stage motion with fast short-stroke Galvoscanner motion.

About Polaris Motion

Polaris Motion specializes in control solutions for CNC machines in laser-based manufacturing, diamond tool cutting and grinding of optical surfaces and for specialized CNC machines in other high performance areas.

Our catalog (5MB) may be downloaded here.

Best regards,

Mile Erlic

Polaris Motion

www.pmdi.com

merlic@pmdi.com