Do You Need to Make Better, Faster Laser CNC Machines?

Create large parts, with fine detail, at extreme speeds!

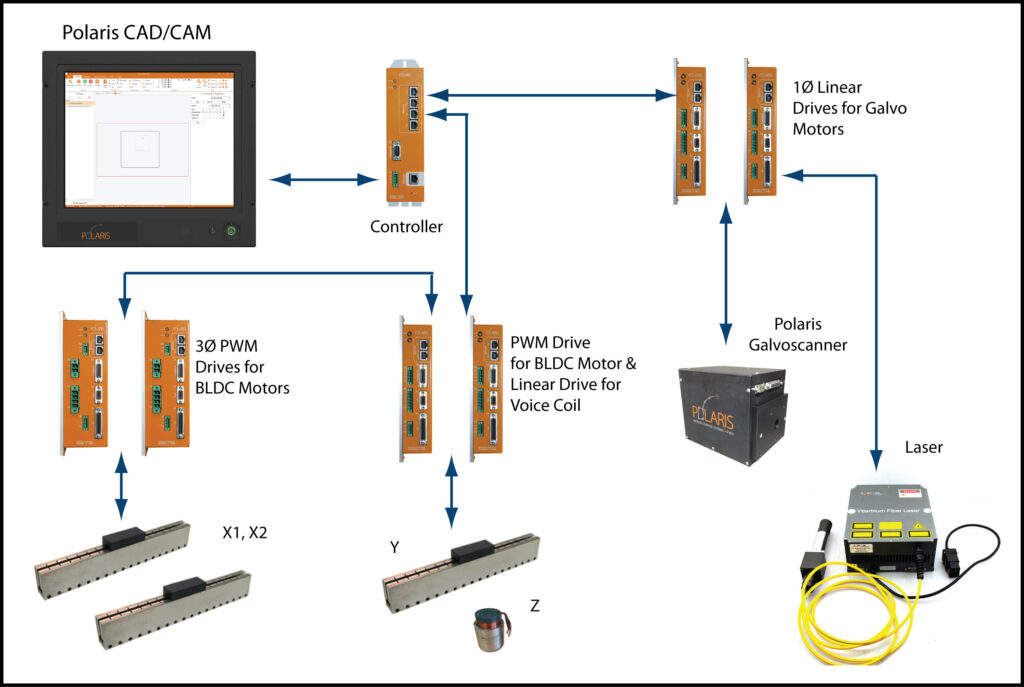

Purchase a Polaris CNC motion control system, and synchronize your long-stroke XYZ stage with a fast moving Galvoscanner to combine range, speed and detailed part processing, all on a single platform. Advanced Polaris Motion technologies coordinate stage and Galvoscanner motion and synchronize lasers.

Everything is brought together by Polaris CAD/CAM, our easy to use operator software. Polaris Galvoscanners, controllers and drives are integrated into an XYZ stage quickly and a machine is made fully functional in days and weeks instead of months.

See us at IMTS Booth E4661, Chicago Illinois, Sept 12-17, 2016

Polaris CNC Architecture for CNC Laser Machines

Applications are far-ranging from 3D printing, robotics, metal, glass and polymer processing, to cutting and material removal. Industries served include automotive, aerospace, device manufacturing, micro electronics, semiconductors, printed circuits and more.

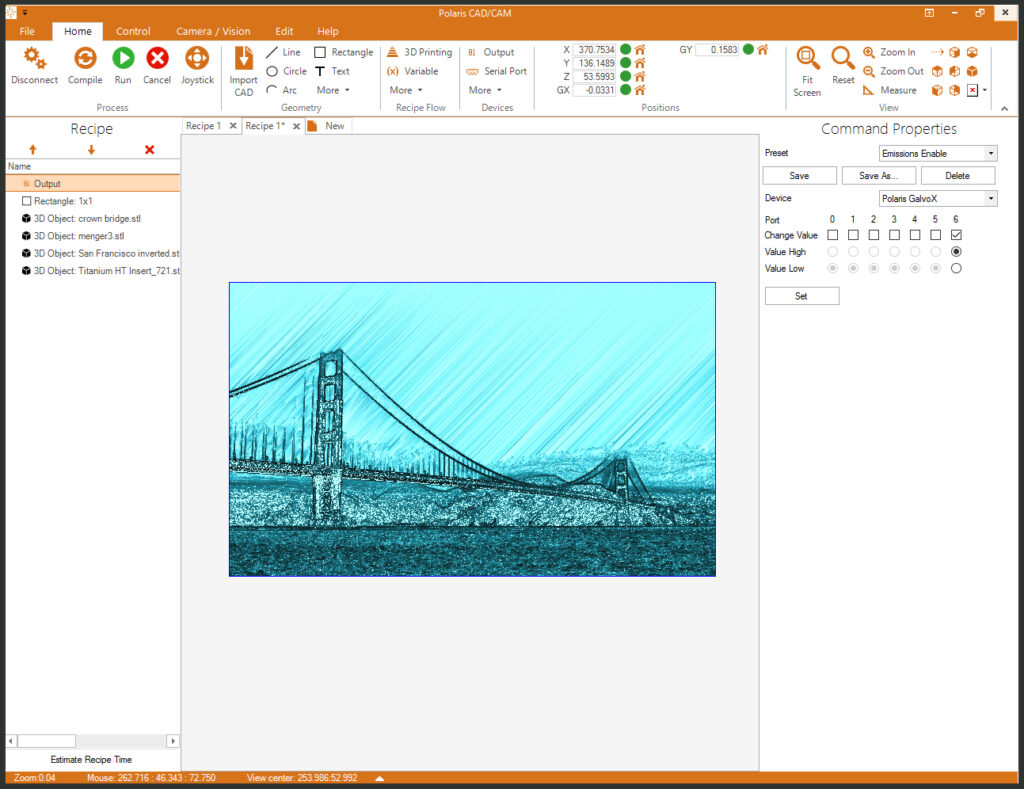

Polaris CAD/CAM

Polaris CAD/CAM is easy-to-use, off-the-shelf software that enables immediate control of your laser machine. You may design your own 2D and 3D parts, import designs from other programs, control a laser source, Galvoscanners, positioning stages, inspection cameras and other devices.

IMPORT 2D AND 3D CAD FILES

DXF, DWG, STL, Gerber and NC Drill files may be imported to Polaris CAD/CAM and used for laser machining. STL files can be sliced and hatched and used for 3D laser printing and 3D laser engraving. DXF, DWG and Gerber files can be hatched and offsets added for beam spot compensation. Use imported CAD files to prepare complex laser machining recipes.

DRAW OBJECTS

Lines, circles, arcs and rectangles are easy to draw in Polaris CAD/CAM. You can draw them by hand and/or add precise parameters for size and position. You can draw polylines and polygon shapes with a special easy to use tool. All closed shapes can be hatched with one of the hatching types (lines, cross-hatching, dots, contours). Select motion speed and laser parameters for each shape, groups of shapes or the whole recipe.

CREATE COMPLEX RECIPES WITH FLOW TOOLS

All the parameters in the recipe such as size, position, motion and laser parameters can be entered as variables. It is an easy way to change and control parameters for the entire recipe. In addition, logical commands may be used to create complex, yet flexible and easy-to-control laser machining recipes. Use mathematical expressions, constants and formulas to create complex geometries.

Polaris Galvoscanner

Add a Polaris Galvoscanner with Polaris control system to your stage, laser source and machine vision system for a complete machine.

Polaris Galvoscanners employ digital encoder technology for consistency, repeatability and accuracy. Powerful tuning optimizes both dynamic and stationary performance for high quality ablating, marking, cutting, drilling and patterning.

All of the advantages of Polaris control are brought forward including powerful path-planning, comprehensive and full-featured laser trigger logic, remote system diagnostics, and data acquisition. Data is easily analysed using digital oscilloscope and frequency based real-time graphing tools.

Advanced features include F-Theta lens barrel-pincushion distortion correction, infinite field of view (IFOV) and pulse-on-demand (POD) laser triggering.

Polaris Galvoscanners may be mounted to any type of stage from simple XYZ stages to robots including tripods, hexapods, and industrial robot arms. Polaris has native robot support with native management of joint and Cartesian coordinate systems.

A wide range of Galvoscanner mirrors and F-Theta lenses are available.

About Polaris Motion

Polaris Motion specializes in control solutions for CNC machines in laser-based manufacturing, diamond tool cutting and grinding of optical surfaces and for specialized CNC machines in other high performance areas.

Our catalog (2MB) may be downloaded here.

Best regards,

Mile Erlic

Polaris Motion

www.pmdi.com

merlic@pmdi.com