Infinite Field of View (IFOV)

A Galvo scanner’s field of view is typically around 100x100mm. By attaching a Galvo scanner onto an XYZ stage, and by moving the scanner around, one is able to make larger parts, as big as the XY travel of the stage. Traditionally, a technique called step and scan has been used to make big parts. The Galvo scanner marks an area the size of its field of view, it is then moved by the XYZ stage and stopped for another scan. This step and scan process is repeated until the part is completed.

Step and scan has some drawbacks. For one, continual starting and stopping may decrease the speed of production. Second, an inaccurate alignment between scanning areas may lead to unacceptable “stitching errors.” Third, complex part programming is required, with separate part programs for stage motion and Galvo motion. Managing the laser trigger with respect to actual spot position may lead to additional errors that show up as unacceptable marking flaws.

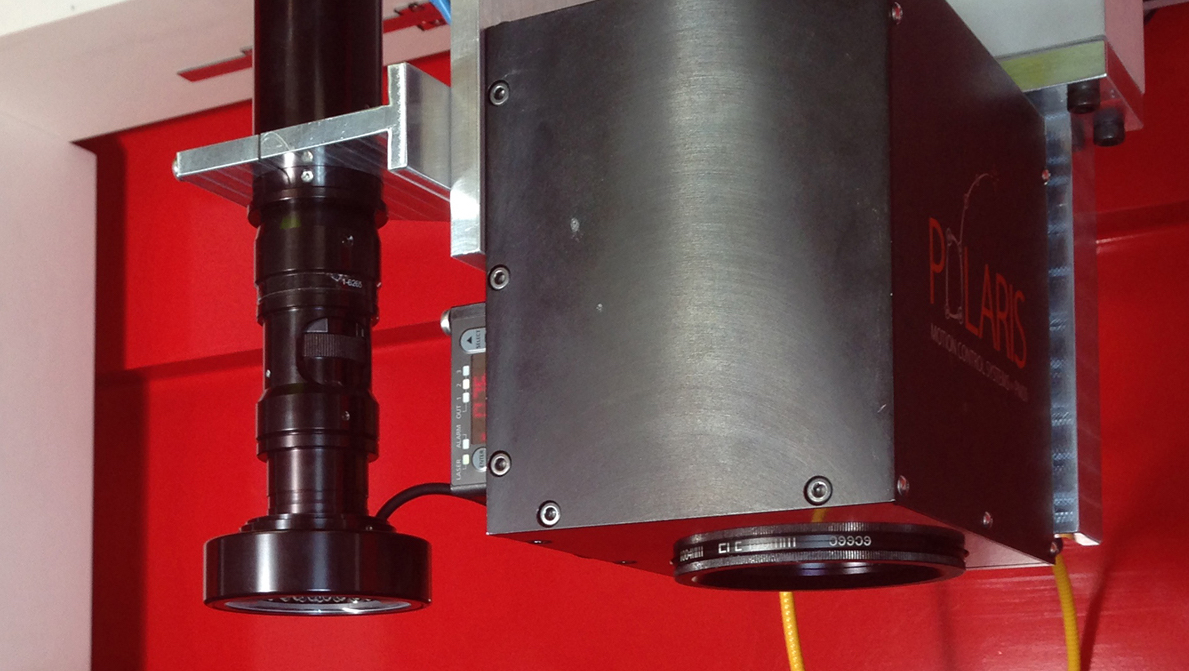

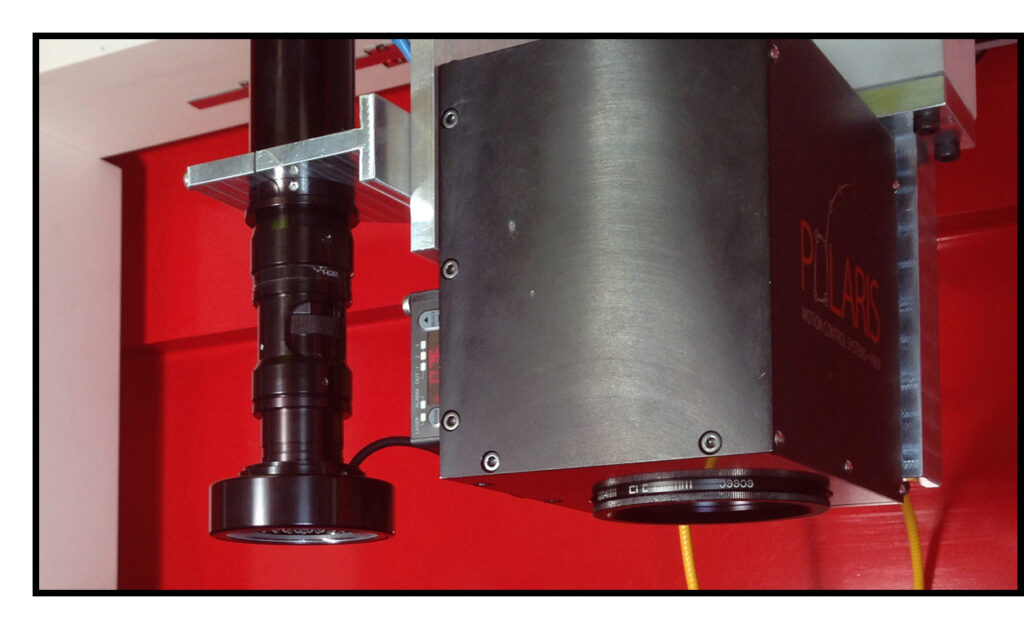

Polaris’ infinite field of view (IFOV) solves the issues inherent to step and scan. Advanced algorithms are used to coordinate stage and Galvo scanner motion seamlessly. Simply feed in the desired part program and the system coordinates stage and Galvo scanner motion automatically. Further, the laser trigger is synchronized with the combined motion for no missed triggers. Large parts are completed quickly and they look great.

IFOV in Action

At Polaris Motion, we specialize in IFOV. It’s one of our main focus areas! We provide a CNC motion control system that makes IFOV setup easy. Our IFOV algorithms provide the most consistent and natural motion behavior of both stage and Galvo scanner, and the way we coordinate laser triggering with motion is perfectly reliable with no missed pulses.

Our IFOV technology is compatible with all combinations of stages and Galvo scanners. You may use any servo motor for XYZ stage control. Galvo scanners having XY2-100, SL2-100 connections or direct connection from motor leads and encoders may be used.

If you desire great performance and wish to have no trouble setting up and maintaining your IFOV capable machine, then you’ve come to the right place.

See more IFOV videos here.

About Polaris Motion

Polaris Motion specializes in motion control solutions for CNC machines in laser-based manufacturing, diamond tool cutting and grinding of optical surfaces and for specialized CNC machines in other high performance areas.

Our 32 page catalog (5MB) may be downloaded here.

Mile Erlic

Polaris Motion

www.pmdi.com

merlic@pmdi.com