Laser Micromachining Made Easy with Polaris CAD/CAM – From Design File to Finished Part and Inspection in a Few Steps!

Polaris CAD/CAM is new, advanced software used to control laser CNC machines.

Polaris CAD/CAM helps make laser micromachining and 3D printing easy. It’s a single piece of software for the machine operator to design parts, import part files, run the machine and inspect the finished product. Fully featured, it’s used to control the laser source, positioning stage, Galvoscanner, and machine vision camera.

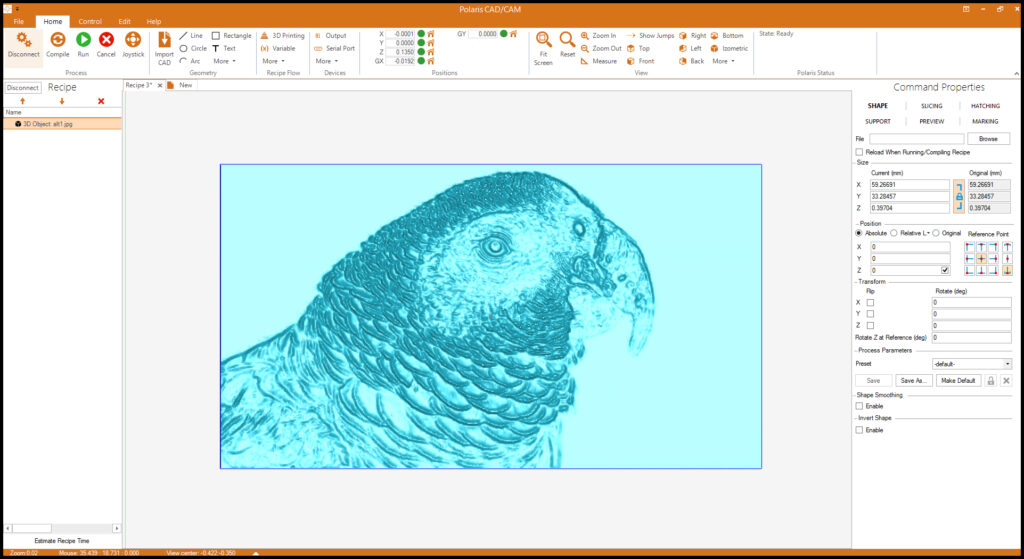

Import 2D and 3D CAD Files

DXF, DWG, STL, Gerber and NC Drill files can be imported into Polaris CAD/CAM. STL files can be sliced and hatched and used for 3D laser printing and laser engraving. DXF, DWG and Gerber files can be hatched, and offsets can be added for beam spot compensation.

Draw Objects in Polaris CAD/CAM

Lines, circles, arcs and rectangles are easy to draw. You can draw parts by hand, and add precise parameters for size and position. You can draw polylines and polygons with easy-to-use tools. All closed shapes can be hatched with lines, hatchings, dots, and contours. Select motion speed and laser parameters for each shape, groups of shapes or the whole recipe.

Create Complex Recipes with Recipe Flow Tools

All the parameters in the recipe such as size, position, motion and laser parameters can be entered as variables. It’s an easy way to change and control parameters for whole recipes. Logical commands can be used to create complex, yet flexible recipes. Use mathematical expressions, constants and formulas to create complex geometries.

Control Positioning Stages and Galvo Scanners

Polaris CAD/CAM has a stitching tool and infinite field of view (IFOV) to combine fast motion of the Galvoscanner and the long stroke motion of the stage. Stitching allows the division of a large object into tiles, and centering each object in the Galvo field. Infinite field of view synchronizes and coordinates stage motion and Galvoscanner motion automatically.

Device Control via I/O and Serial Port

Hardware in the laser CNC machine can be controlled through digital and analog I/O and serial port commands. Commands can be included in the recipes or added as special buttons in the user interface. Support for specific devices may be developed on request.

Control Positioning Stages with a Virtual Joystick

Polaris CAD/CAM has a Virtual Joystick to control the positioning stage manually. There are preset positions for load-unload and automatic motion between camera and laser positions.

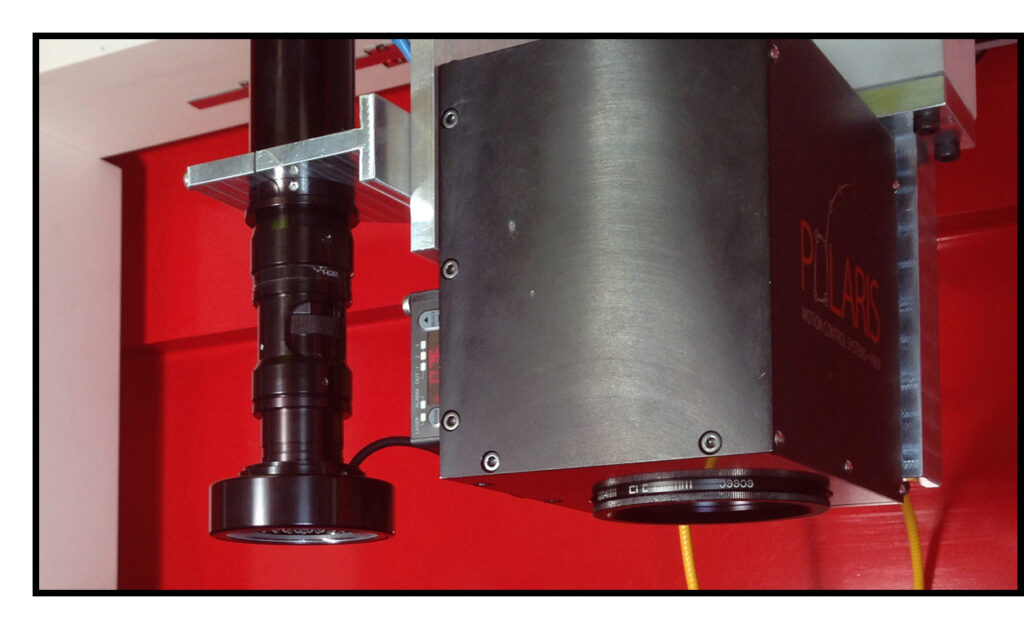

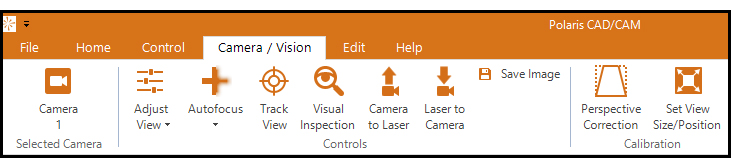

Machine Vision

Polaris CAD/CAM integrates machine vision with laser machining processes. Machine vision can be used to inspect actual markings or it can be used to super-impose fabrication trajectories onto the image of the cut part. Camera view is calibrated to match the stage coordinates. Several cameras may be used, for both wide and zoomed-in views.

The camera view can be co-linear with the laser or it can be off-axis. For off-axis views, the laser and camera may be shuttled back and forth over the feature of interest. Other camera uses include auto-alignment and auto-focus.

About Polaris Motion

Polaris Motion specializes in control solutions for CNC machines in laser-based manufacturing, diamond tool cutting and grinding of optical surfaces and for specialized CNC machines in other high performance areas.

Our 36 page catalog (2MB) may be downloaded here.

Polaris CAD/CAM videos may be seen here.

Mile Erlic

Polaris Motion

www.pmdi.com

merlic@pmdi.com