Motion Control Server Software

Polaris Server is the embedded motion control software application that executes under Linux on a quad core Intel CPU located inside a Polaris UniverseOne™ motion controller. Polaris Server communicates to client software on the one side and to the Mercury™ network of devices on the other side.

Inside Polaris Server there is a general-purpose motion engine, a G-code engine, high speed data acquisition functionality and many other functions. A high performance setpoint generator maximizes the machine’s throughput by using its axes constraints.

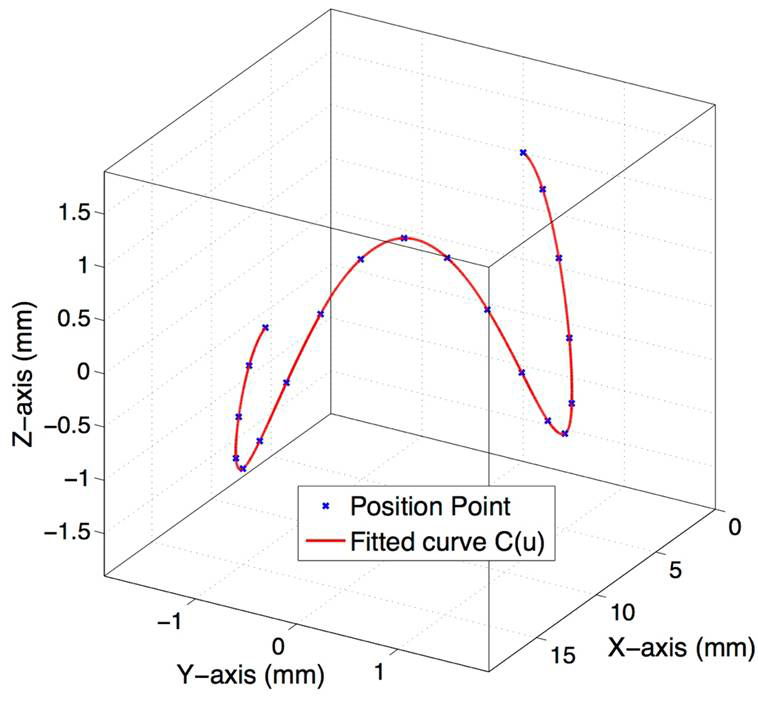

Linear, Circular, Spline Interpolation and Merging

For multi-axis coordinated motion, the setpoint generator performs linear, circular or spline interpolation according to the program instruction. Merging is a technique that is applied when the angle between path segments is non-zero. The Polaris setpoint generator has the ability to merge the following path pairs: line-line, line-arc, and arc-arc.

Minimum Time Setpoint Generation

Unequalled by any, the Polaris UniverseOne™ setpoint generator uses the maximum ratings of each motor in a machine to generate the tool path. Approaching corners, the machine decelerates as fast as it can and it ramps up the speed as fast as possible as it comes out of corners in to the straights. The motors’ velocity, and acceleration limits are never violated. Part files always complete in the minimum amount of time possible.

Constant Velocity Setpoint Generation

Maintaining constant velocity along a toolpath is important in many applications such as welding and dispensing. The fastest constant speed may be achieved by identifying the slowest motion axis and adjusting toolpath speed until a constant speed is achieved along all parts of the path. The Polaris Motion Simulator is useful for performing this procedure.

Independent Axes Motion

In many applications, motion axes need to run independently. The motors in the machine need to start and stop at different times. This functionality is available in the Motion Control Interface (MCI) library API.

Coordinated Axes Motion

Coordinated motion is needed in applications and processes where all motors on the machine need to start and stop at the same time. The motion can be specified in 2D or 3D space. This type of motion is common in applications such as 3D welding and dispensing where the tool needs to follow lines, arcs or splines precisely. Coordinated motion moves are supported using the MCI library API and G-code.

Handwheel Control

The Polaris handwheel feature uses a combination of hardware, firmware and software to enable an operator to control a machine axis using a manual pulse generator. A mechanical switch us used to select the axis to be moved. Typical uses include machine calibration, manual jogging and tool changing.

Gantry Axis Setup & Control

A gantry axis has a pair of identical linear servomotor and drives. The servomotors are arranged in parallel and they are connected with a mechanical bridge. The drives receive the same setpoints and the goal is for the two servomotors to move identically. This is accomplished with a multi-input, multi-output servo feedback regulator executed in the Polaris drives. The two axes share real-time encoder information with one another across the Mercury™ network, any skew error is eliminated and the gantry moves as a single unit. A gantry is useful as it provides a wide stance for mechanical stability and it is able to compensate for a shifting load that moves along the bridge.

Setpoint Generator

The Polaris UniverseOne™ setpoint generator accepts path points from the G-code function or from an alternate program. The distance between the points may be large and uneven and it’s the job of the setpoint generator to fill in the gaps with closely-spaced setpoints. The setpoint rate may be 1kHz, but it may be 20kHz, 100kHz or more. The rate is settable.

Give us a call or ask a question! Me and our team are always happy to help!

Tom Erlic, Business Development

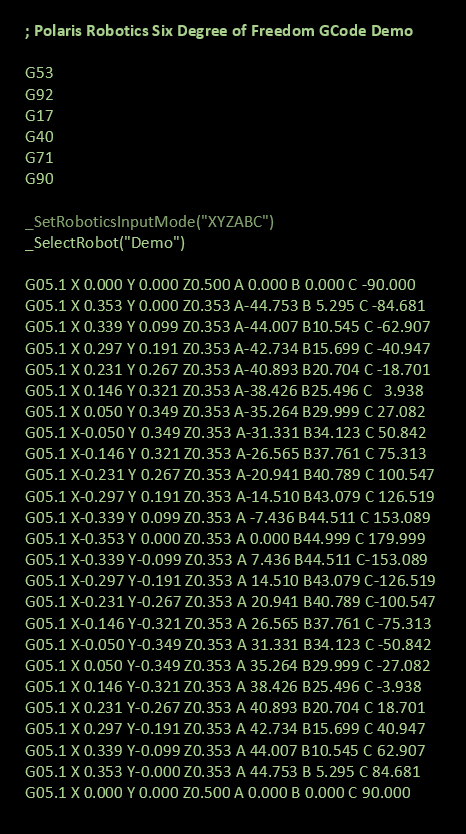

G-code Language & Engine

>>Learn More

Polaris Motion has been offering advanced CNC G-code control since 1996, and it is a center piece of the Polaris UniverseOne™ motion control system. Our implementation adheres to the EIA-RS274D G-code standard, and it supports 3-Axis, 5-Axis and 9-Axis CNC machines. Polaris G-code’s core ability provides precise, coordinated multi-axis motion control; it is an industry leading technology, and it has un-equaled breadth and depth while considering both mechanical and laser-optic motion axes.

Infinite Field of View (IFOV)

>>Learn More

Laser Galvoscanners are extremely fast, but they have a limited field of view. On the other hand, BLDC motor driven XYZ stages have a long stroke but compared to laser Galvo scanners they are slow. By combining a slow, long stroke XYZ stage with a fast, short-stroke laser Galvoscanner the best of both worlds is achieved when Polaris Motion’s IFOV technology is used.

Linear, circular and spline commands are issued, and the toolpath is separated into stage motion and laser motion seamlessly.

Laser Control

>>Learn More

Laser control is required for many manufacturing processes such as cutting, drilling, welding, etching, engraving and surface structuring. Precise laser control is needed for powder bed fusion (PBF) and for directed metal deposition (DMD). Lasers are used for material altering processes such as annealing and quenching for metals, and modifying impedance in semiconductors.

For each of these processes, there is a preferred technique for controlling the delivery of the laser energy. The two broad classes of lasers are continuous wave (CW) and pulsed. CW lasers are typically lower cost and have the advantage of high average power. Pulsed lasers have lower average power, but the short pulse photon energy breaks the material’s chemical bonds instead of burning. The heat affected zone (HAZ) is minimized, cuts are clean and addition material post processing such as de-burring is often unnecessary.

Using advanced hardware and firmware, Polaris UniverseOne™ motion control systems provide customers with the widest assortment of laser source control techniques for both pulsed lasers and CW lasers. Power is precisely controlled in real time as the laser traverses the tool path. Over-burning becomes a thing of the past and the highest quality processing results are achieved.

Polaris UniverseOne™ drives, SL2-100 interfaces and other modules come equipped with a laser control interface (LCI) for easy integration with a wide variety of laser source manufacturers.

Machine Calibration

>>Learn More

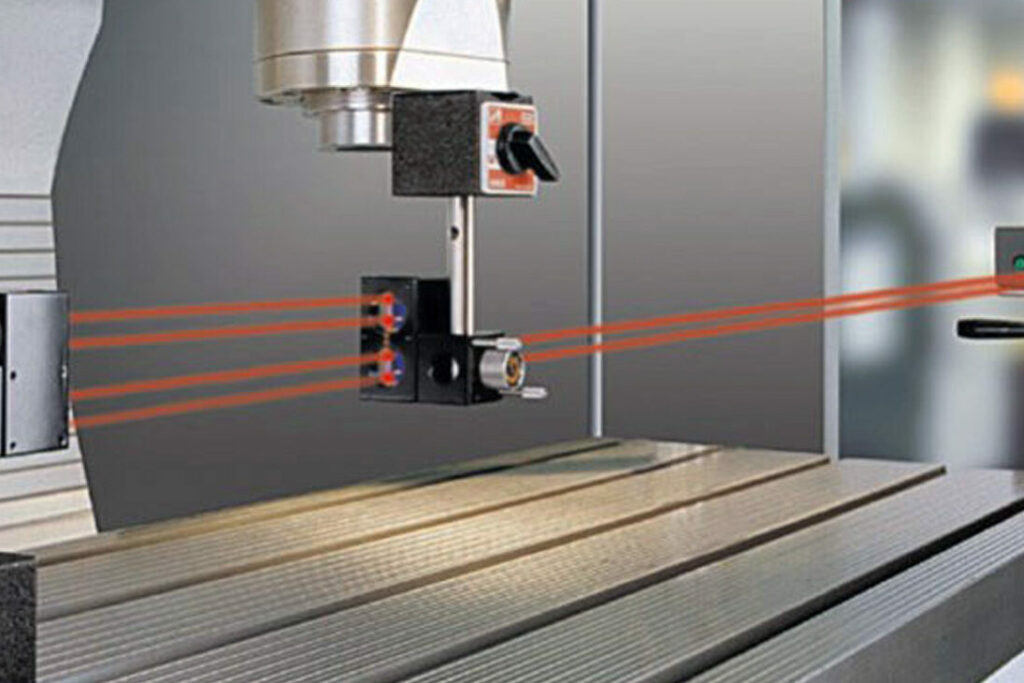

A high degree of accuracy is necessary for many high-end machine tool applications. For some equipment micron precision is require and for others, accuracies in the single digits of nanometers are needed.

Polaris UniverseOne™ motion control systems come equipped with the tools that help achieve these results. Techniques are included for both mechanical stage calibration and for optical lens calibration. In both cases it is important to have an accurate external reference such as laser interferometer in the case of the mechanical stage or an accurate glass calibration plate for the laser Galvoscanner.

Mechanical Stage Calibration

>>Learn More

For stage calibration, Polaris UniverseOne™provides motion control software for backlash, encoder, and abbe error compensation. Experiments are conducted and measurements from a laser interferometer or tracker are entered along with the corresponding encoder values. Polaris UniverseOne™ algorithms provide calibration tables that run in real time for accurate machine tool operation.

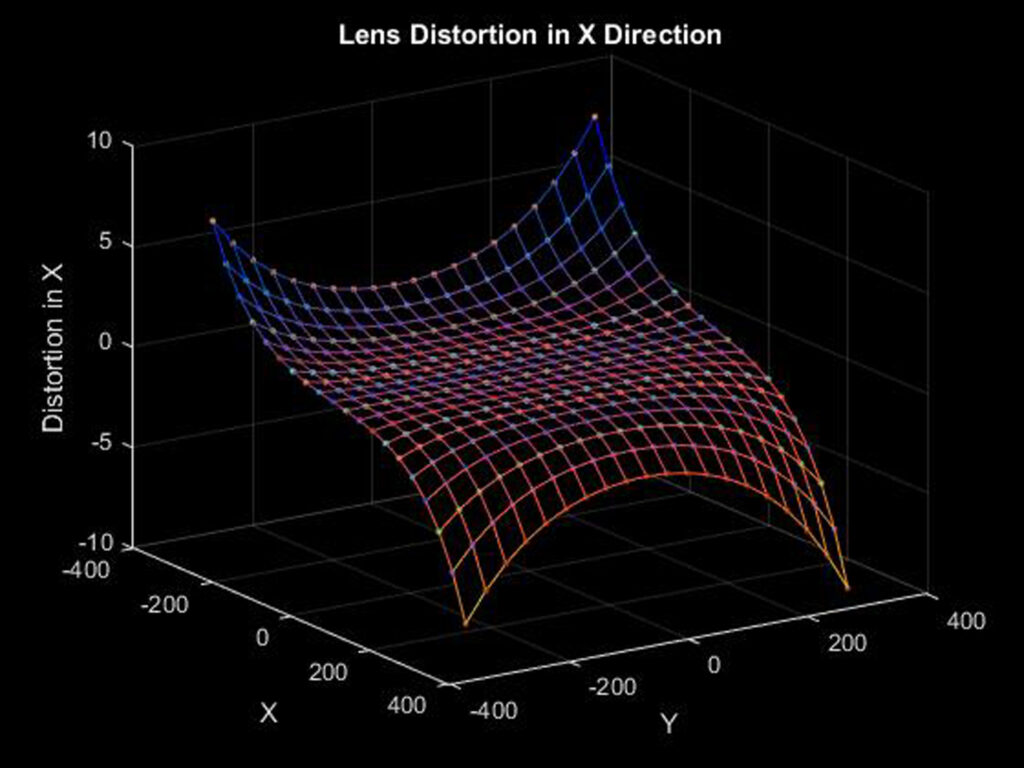

Optical Galvoscanner Calibration

>>Learn More

Polaris UniverseOne™ systems offer calibration tools for 3rd party XY2-100, SL2-100 and HSSI Galvoscanners and for native Polaris Galvoscanners. A grid of fiducials is created with the laser Galvoscanner and these are compared to results taken from a machine vision system. An advanced curve fitting algorithm is executed to create a highly accurate calibration grid that produces accurate real-time results. The technique applies for both 2D and 3D Galvoscanners.

Machine Tool and Robot Geometry

>>Learn More

Robotics is supported by Polaris UniverseOne™ motion control software systems in a unique and novel way. Robots can be serial, parallel or hybrid manipulators. The mathematical mapping between robot pose, described in the Cartesian coordinate system, and the robot’s joints is the forward and inverse kinematics.

Polaris UniverseOne™ controllers encapsulate the forward kinematic, inverse kinematics and constraints in a geometric or world model. This encapsulation creates an abstraction that allows for the description of motion to occur in the Cartesian space.

By performing this mapping, a separation is created between the robotics, path planning and setpoint generation. All standard tools can be employed including standard 5 axis CAM packages and 5 axis G-code.

All machine types can be supported in this manner, including 5-Axis CNC machine tools, serial industrial robots, precise 6DOF Hexapods and more.

Motion Control System Simulator

>>Learn More

Polaris UniverseOne™ Simulator is a motion control software program that simulates the generation of tool paths exactly without the need for Polaris Motion hardware. The simulator accepts G-code files as an input and generates position setpoints which can be analyzed.