The Fastest Constant Speed Can Make a Huge Difference for Advanced Manufacturing

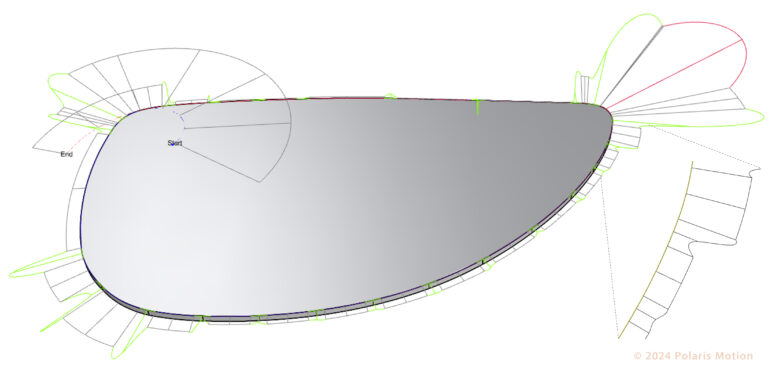

Constant Speed Curvature Graph

Constant Speed Curvature Graph

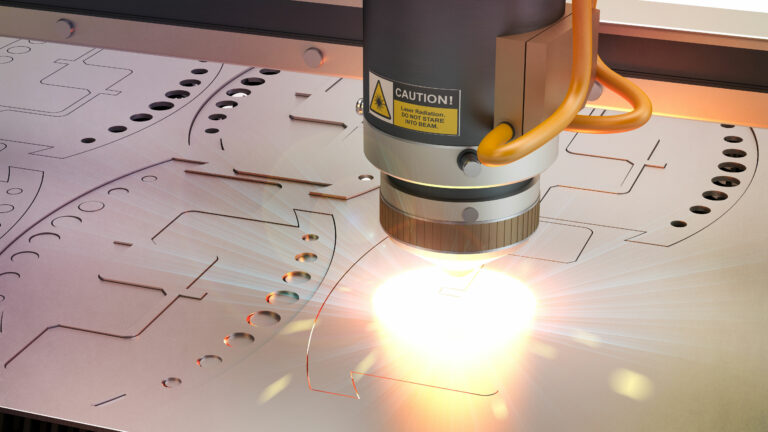

Laser control is required for many manufacturing processes such as cutting, drilling, welding, etching, engraving and ablation. Fine laser control is needed for powder bed fusion (PBF) and for directed metal deposition (DMD). Lasers are used for material altering processes such as annealing and quenching for metals, and modifying impedance in semiconductors. For each of…

Polaris Laser Wobble Technology Polaris Motion’s infinite field of view (IFOV) is easy to use, and you can use any Galvoscanner. With Polaris Motion, only six settings are needed to configure IFOV. Four of these define the axes selections. One setting turns IFOV on and off, and the last setting chooses how much of the…

Booth Number Correction: BOOTH 4249 PHOTONICS WEST 2019, Feb 5-7, San Francisco Polaris Laser Wobble Technology Laser wobble has been added to Polaris Motion’s laser CNC toolbox. Some other tools include infinite field of view (IFOV), F-theta lens correction, and 3D laser micro machining. Visit us at Booth 4249 – Photonics Weat 2019 to find…

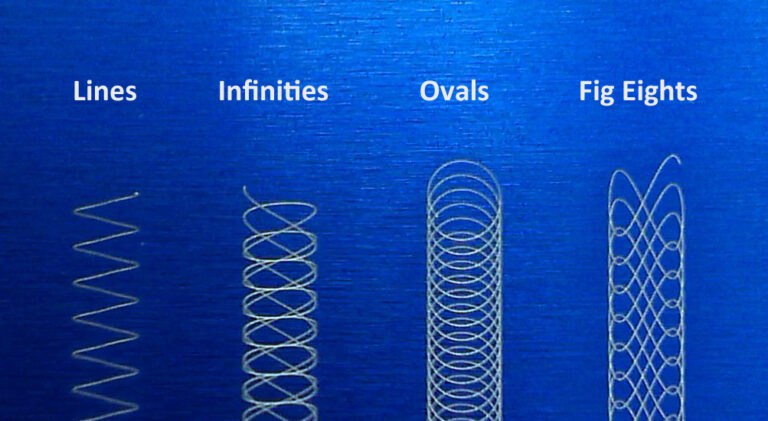

Polaris Laser Wobble Technology Laser wobble has been added to Polaris Motion’s laser CNC toolbox. Some other tools include infinite field of view (IFOV), F-theta lens correction, and 3D laser micro machining. Visit us at Booth 4229 – PW2019 to find out more about these and other powerful techniques. Laser wobble is an effective technique…

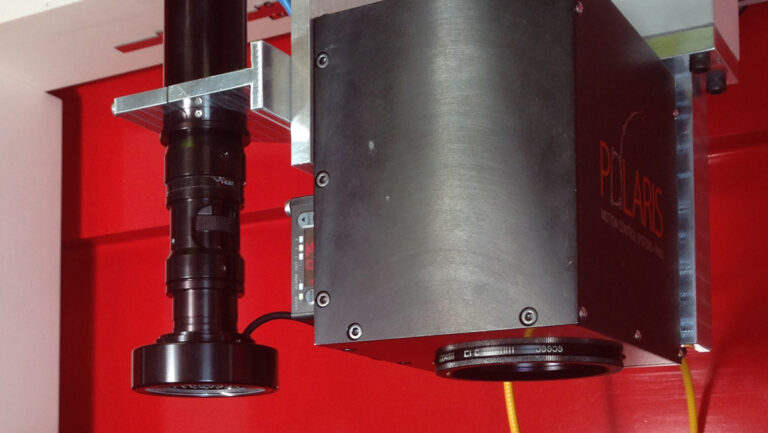

See us at Laser Taiwan 2018, Oct 17-19Booth K401 IFOV with a Precision XYZ Stage and a SL2-100 Galvo Scanner IFOV is a technique used for laser material processing where a fast Galvo scanner with its small field of view is mounted onto an XYZ stage that is slower but has a large stroke. The…

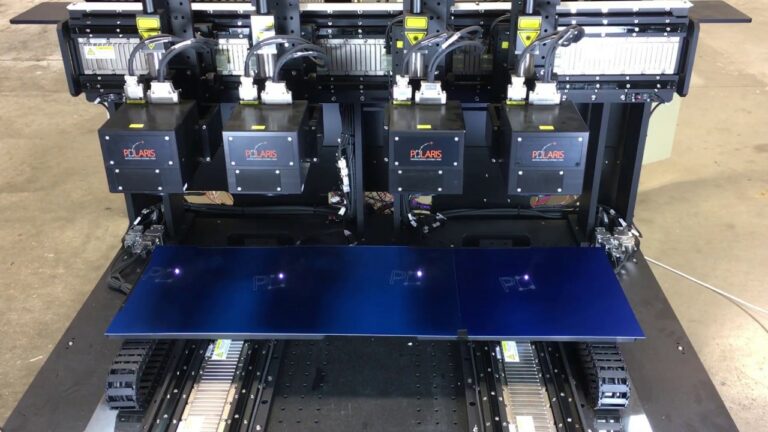

Multiple Galvo Scanners & IFOV in Action Polaris Motion has extended its infinite field of view (IFOV) technology to handle multiple Galvo scanners and stages. Multiple Galvo scanners can now share common stage axes or they can use independent stages. This offers our customers great flexibility when designing their machines to handle mass manufacturing requirements…

A Galvo scanner’s field of view is typically around 100x100mm. By attaching a Galvo scanner onto an XYZ stage, and by moving the scanner around, one is able to make larger parts, as big as the XY travel of the stage. Traditionally, a technique called step and scan has been used to make big parts….

Many new ideas in CNC laser micromachining and 3D printing need a platform that doesn’t constrain the designer’s creativity. This is where a Polaris CNC motion control system is of value. The high data rates, flexible programming environment, ease of use and high reliability provide an ideal platform to realize those ground breaking ideas. Control…

ASPE Annual Meeting, Charlotte 2017 Polaris Software Release V2.6 Ultra Precision Spindle Motor Controller New Catalog October 2017 Visit us at the annual meeting of the American Society for Precision Engineering (ASPE) located in Charlotte, North Carolina this year at the Westin Hotel. Tom Erlic, President will be there at booth 308. We are excited…